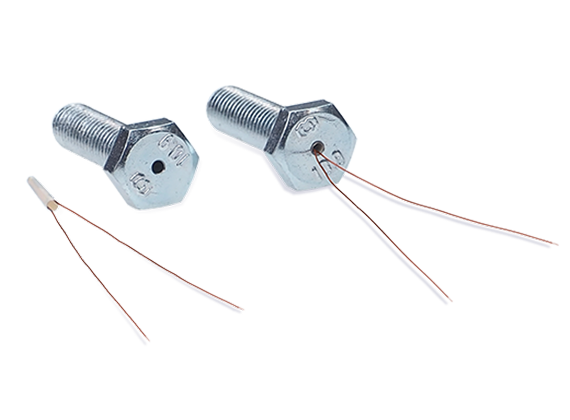

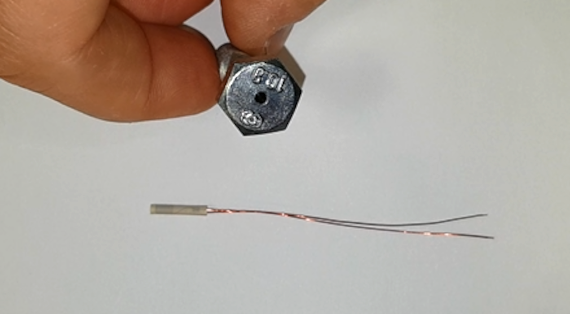

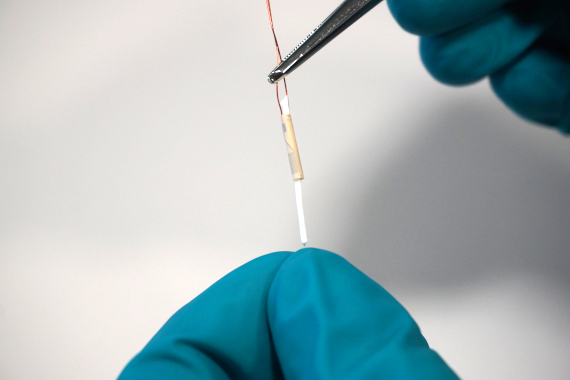

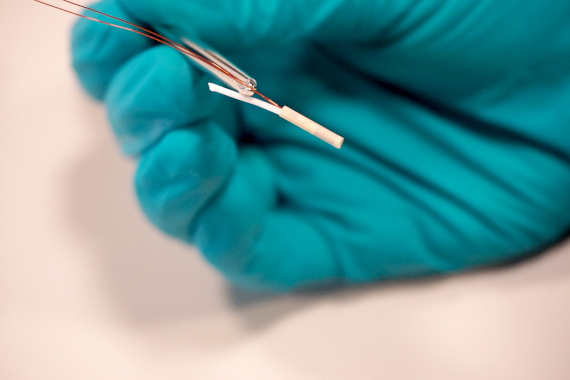

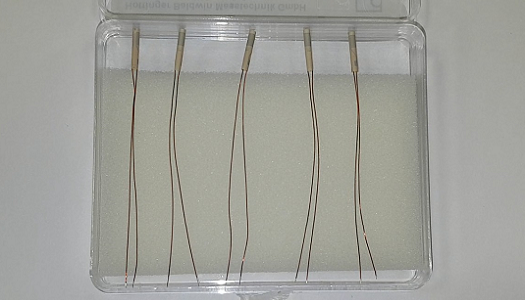

1. In the next step, take out one of the strain gauges from its package.

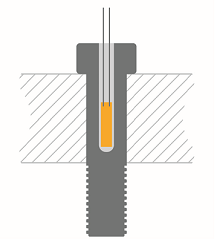

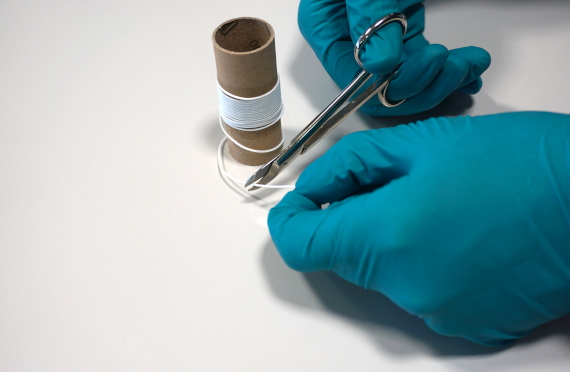

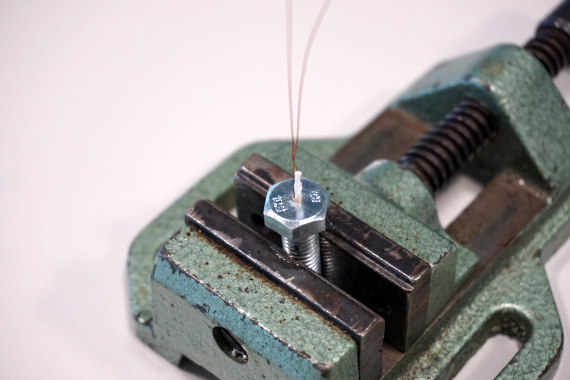

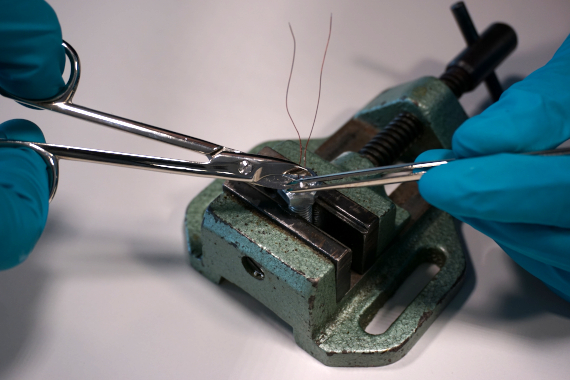

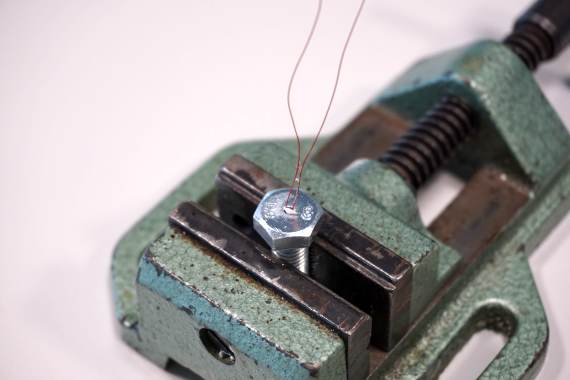

2. Cut an approximately 20mm long piece of teflon cord from the supplied roll with scissors. Grasp the strain gauge at the enameled copper wires with tweezers and insert the teflon cord into the cylindric strain gauge. Place the prepared strain gauge on a clean surface.