TEDS: Plug and Measure with a Digital Electronic Data Sheet in the Transducer

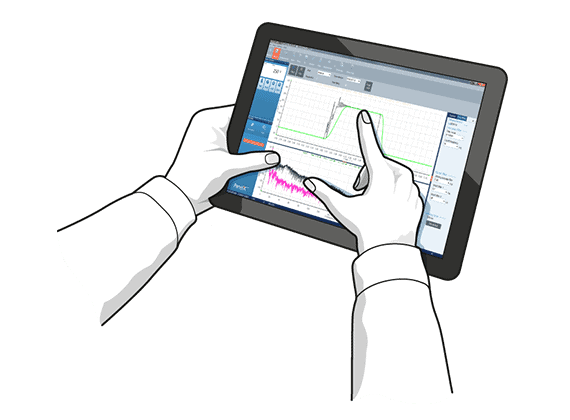

TEDs (Transducer Electronic Data Sheet) allows you to just plug and play in all your test and measurement tasks.

The digital datasheet holds all relevant transducer characteristics and calibration data for setting up the whole measurement chain in seconds. All other relevant meta data are also transferred from sensor to your measurement channel as well and makes it a traceable overall solution from sensor to result. This significantly simplifies handling of sensors.

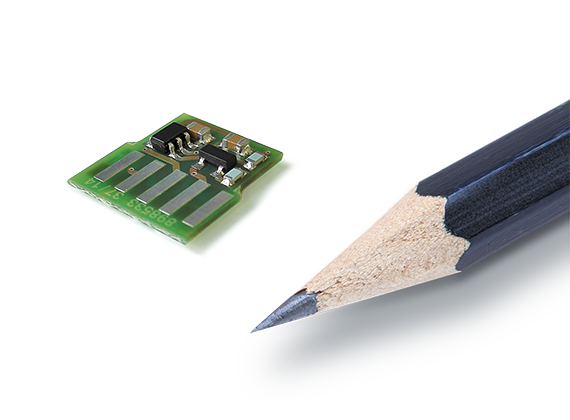

Just choose from off-the-shelf sensors and amplifiers to your needs and start the journey. The TEDS chip is either already integrated in the sensor, or if this is not applicable can be installed in the transducer plug as well – it should be a fix configuration at the end without any adapters in between.

Working with TEDs – Benefits

Reduce setup time from minutes to seconds by auto configuration of amplifier inputs right after plugging (plug & measure)

Automate your calibration process by software warning for recalibration

Maximize testing time

Reduce maintenance time by improved diagnostics

Simplify asset management by going digital (TEDS + PDF data sheets)

Increase Quality and Reliability in Your Daily Work

Use the true calibration data stored in TEDS in your sensor together the calibration data and certificate from your device

Reduce manual configuration faults

Improve traceability by linking all meta information of the sensor to test data

Improve sensor traceability by storing data sheets in parallel to unique TEDS ID in your software

Protect Environment by Reducing Print Outs

Your Measurement - Your Choice

Choose Your Sensor

- TEDS in the sensor

- TEDS in the transducer plug

Combine and get started

The transducer characteristics required to set up the measurement chain are stored in the TEDS in the form of an electronic data sheet, which is read by the amplifier. All data is stored in so-called templates in the TEDS chip. These templates can be imagined as tables, where the sensor parameters are listed. The amplifier reads the information and the measurement chain can be set up automatically in no time.

Besides the manufacturer, the serial number and other information, the sensor’s sensitivity, which is the most important information, is, of course, stored in the TEDS

The sensitivity recorded in the test record is stored in all TEDS sensors from HBM coming with a test record which, in general, is included as standard, except for KMR force washers and SLB strain transducers

If a calibration is ordered (e.g. according to the ISO 376 standard), the calibration result can be optionally stored in the TEDS instead of the value recorded in the test record.

Yes, the sensor’s sensitivity (rated output) can be overwritten with new data, for example, in case of recalibration.

With the free HBM software "TEDS Editor", the information can be read and written easily by the TEDS chips.

HBM amplifiers, for example QuantumX, MGCplus, PMX or ClipX allow for writing to a sensor

No, TEDS is based on the IEEE 1451.4 standard which is recognized by many manufacturers.

TEDS Accessories

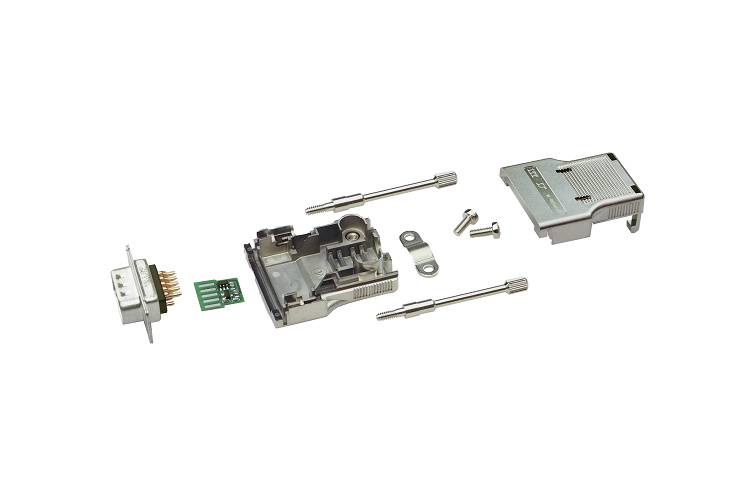

Plug Kit Sub-HD 15pol. (male)

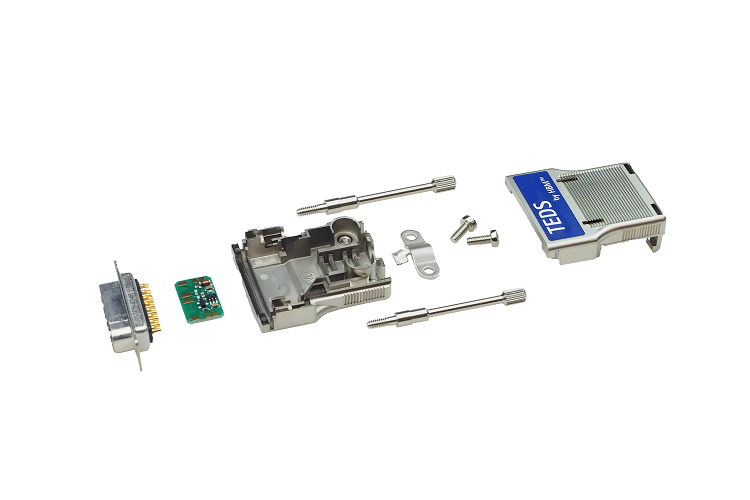

Plug Kit Sub-HD 15pol. (male) with TEDS board

(0-wire) for storing a sensor data sheet;

Housing: Plastic metallized with knurled screws;

Note: TEDS chip is blank.

Article no.: 1-TEDS-HDB-15P

DSubHD 15-pole connector kit (male)

DSubHD 15-pole connector kit (male) including TEDS

chip (1-wire) for storage of a sensor data sheet;

Housing: Metallized plastic with knurled screws;

Note: The TEDS chip comes blank.

Article no.: 1-SUBHD15-MALE

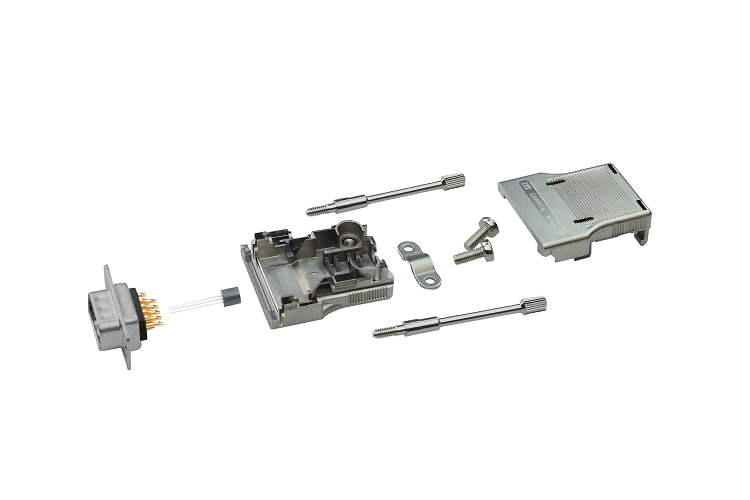

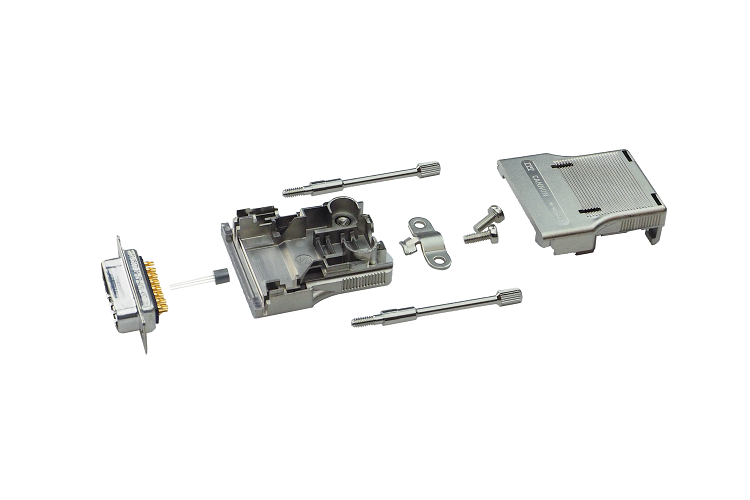

SubD 15-pole connector kit (male)

SubD 15-pole connector kit (male) including

TEDS-board(0-wire) for storage of a sensor data sheet;

Housing: Metallized plastic with knurled screws;

Note: The TEDS chip comes blank

Article no.: 1-TEDS-DB-15P

Plug-Kit Sub-D 15pol. (male)

Plug-Kit Sub-D 15pol. (male) with TEDS chip

(1-wire) for storing a sensor data sheet;

Housing: Plastic metallized with knurled screws;

Note: TEDS chip is blank.

Article no.: 1-SUBD15-MALE

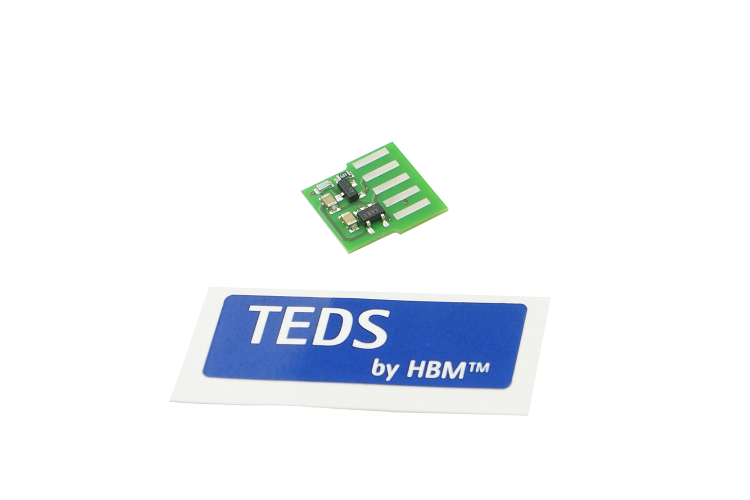

TEDS-board(0-wire) for Sub-HD-15

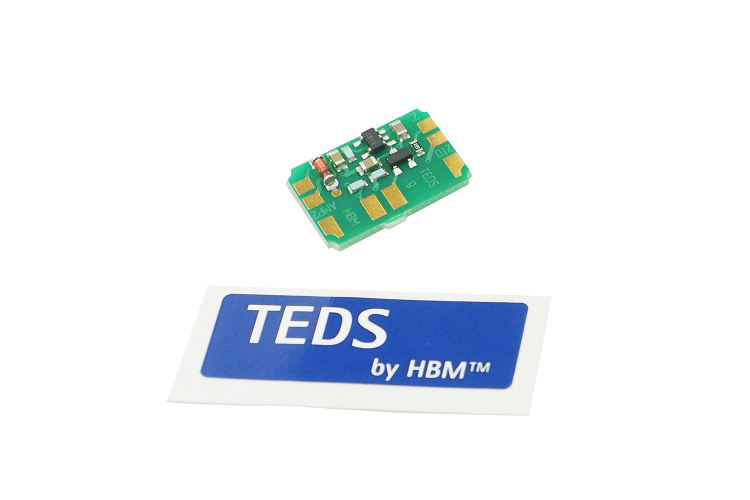

TEDS-board(0-wire) for Sub-D-15

Packg. with 10 pcs. TEDS, 1-wire-EEPROM

Packg. with 5 pcs. TEDS, 1-wire-EEPROM

Product Literature

| 題目/描述 | 語言 | 產品 | 語言 | 內容類別型 |

|---|---|---|---|---|

| 參數表 | ||||

| TEDS - Data Sheet | English | |||

| TEDS - Datenblatt | German | |||

| 裝配指導 | ||||

| TEDS - Mounting instructions | English, German | |||

| 驅動 | ||||

|

IEEE Code for TEDS

Conversion template containing the IEEE codes for TEDS of all HBM transducers. Date: 02/2024 | Size: 2 KB | 多語言 | |||

| Declaration of Conformity | ||||

| 1-KAB, K-KAB (cable) - EU Declaration of Conformity | 多語言 | |||

| 其他 | ||||

|

„TEDS“ Calibration Supplement

Information about the calibration data stored in the TEDS memory Information zu den im TEDS-Speicher abgelegten Kalibrierdaten | English, German | |||

| TEDS - Information | English, German | |||

| TEDS - Informazione | Italian | |||

| 軟體 | ||||

|

TEDS - Editor

Software to read and write TEDS-data (IEEE 1451.4) into and from 1-wire and 0-wire TEDS-modules and backup it on PC. Date: 09/2019 | Version: 3.5R43 | Size: 26 MB | 多語言 | |||