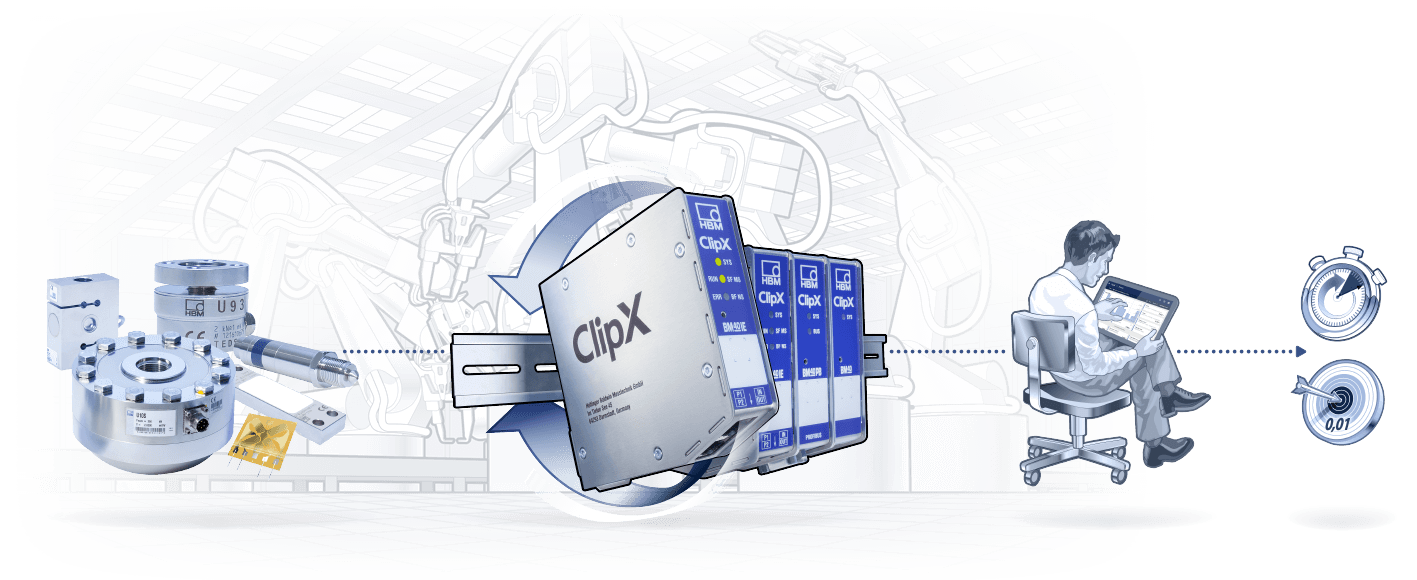

ClipX – The Precise and Easy-to-Integrate Industrial Signal Conditioner

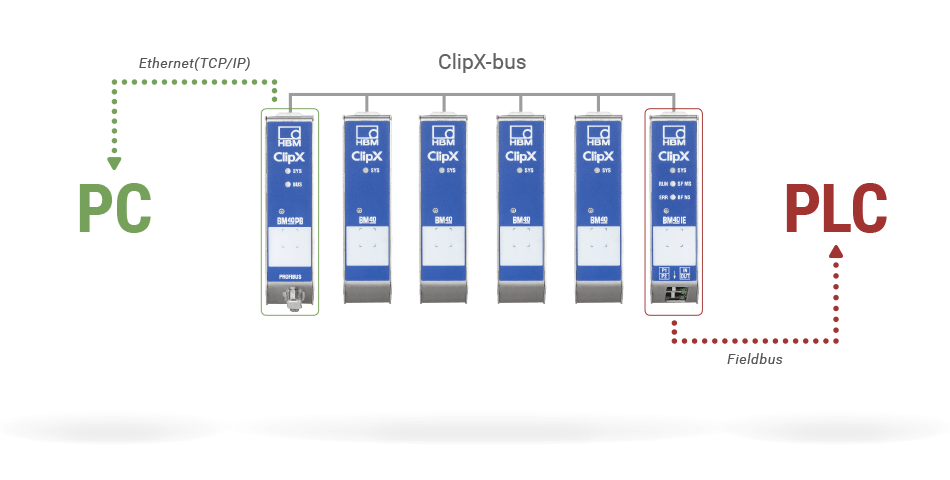

With an accuracy class of 0.01 and an integrated calibration certificate, the interference-proof signal conditioner ClipX is setting new standards in industrial process control. ClipX adapts to your measurement task, regardless of whether it is used with single- or multiple-channel applications, in manufacturing machines, in test benches or for production monitoring. Owing to the Plug and Play principle, up to six devices can be plugged simultaneously in a modular setup and the measured data can be pre-calculated. Unlike conventional measuring signal conditioners, ClipX does not require a separate head module for direct data processing.

ClipX provides all the latest automation interfaces to perfectly integrate the device into comprehensive control concepts. A particular feature is the intuitive web interface that also enables remote operation, parameterization, and diagnosis.

- Accuracy class: 0.01

- Measurement inputs: Full-bridge and half-bridge strain gauges, piezoresistive transducer, potentiometer, Pt100, current, and voltage

- Interfaces: PROFINET, EtherCAT®,PROFIBUS, Ethernet/IP™*, Modbus-TCP, analog (V/mA,) digital-I/O, and Ethernet (TCP/IP)

- IIoT (Industrial Internet of Things): Remote diagnosis, health monitoring and web integration; integrated OPC-UA server