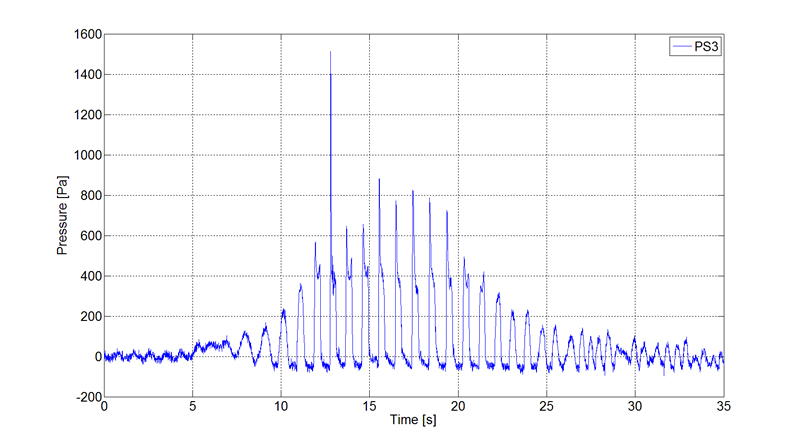

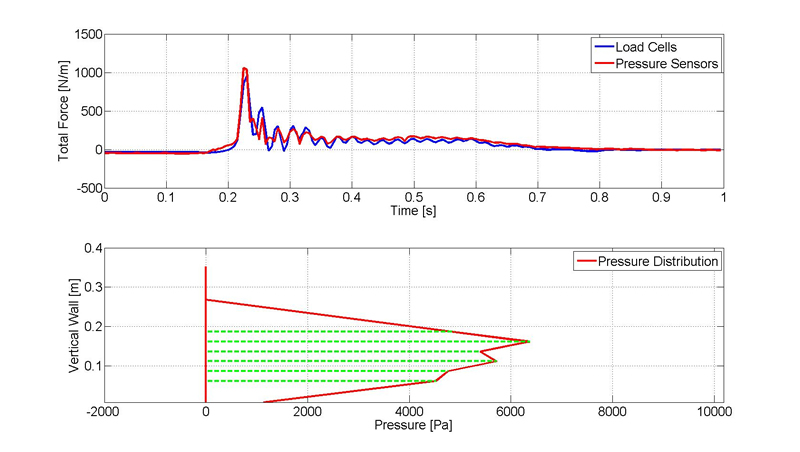

The impact of a wave breaking on a vertical wall is a fast and very powerful phenomenon that is very hard to measure. It is important to measure the total force and its application point generated by the impact of the wave in order to predict the design loads and properly design the seawall. The pressure also is important in the design of the armor of reinforced concrete.

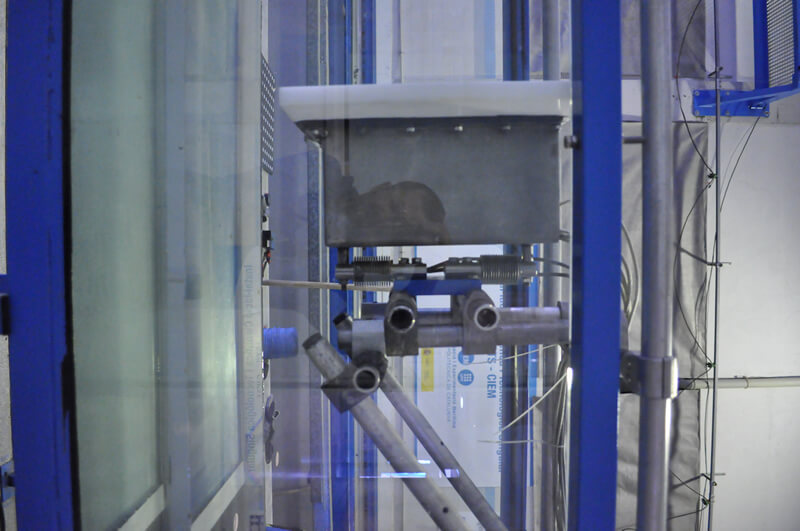

For these purposes, a physical model was built in the Maritime Engineering Laboratory at Polytechnic University of Catalunya (LIM-UPC). The model of the seawall was equipped with 6 P8AP pressure transducers positioned in the impact zone to measure the vertical pressure distribution.

The structure is supported by two Z6C3 beam load cells to measure the total force and the momentum generated by the wave's impact.

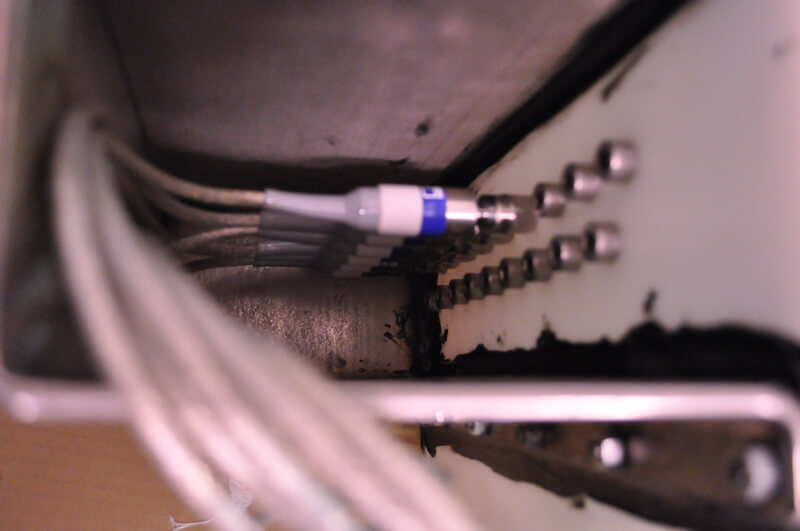

P8AP Absolute Pressure Transducer

The P8AP is an absolute pressure transducer based on a strain gauge sensor with a measuring span of 10 bars and an accuracy class 0.3. The P8AP are IP67, meaning they are weatherproof but not waterproof. For this reason, a box that isolates the sensors from the water is needed.

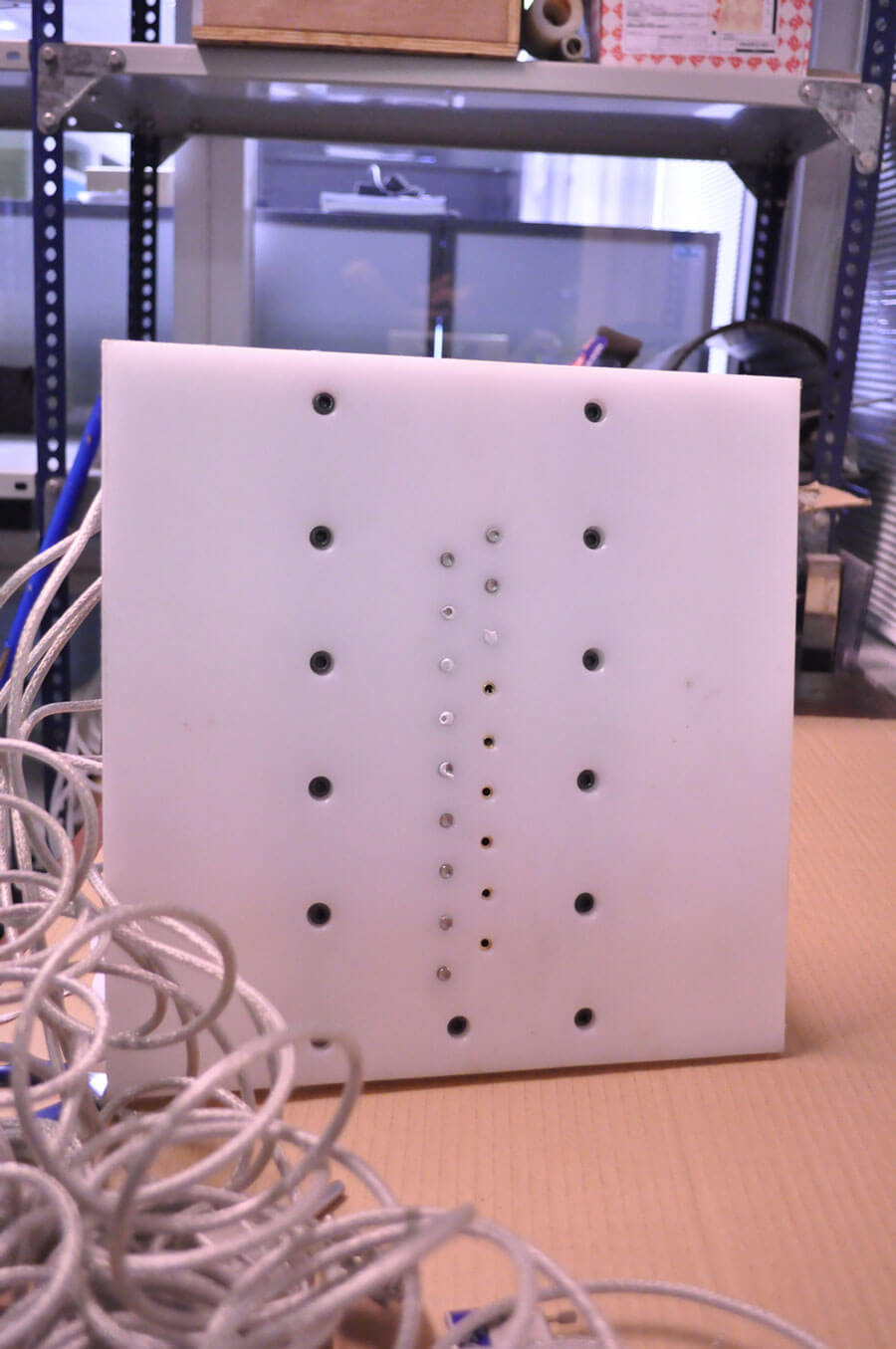

Twenty holes were added to the front wall to enable to try different patterns of pressure sensor positions to be tried. Six holes were plugged with the pressure sensors, and the others were plugged with screws so that the front wall will be waterproof and continuous.

After tests of the pressure sensors in various positions, the definitive pattern was defined with the six pressure sensors placed on the same vertical, with a distance between each sensor of 25 mm.