Tunnels are at the core of our infrastructure. They are found in large cities, mountains and even underwater. They provide connections and shorten distances. But how safe are they?

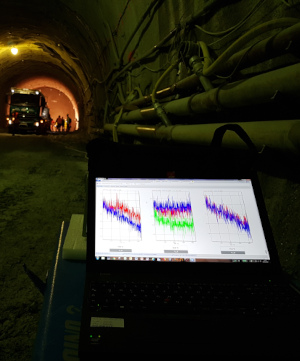

Today, modern monitoring systems allow reliable condition monitoring of tunnels using fiber Bragg technology.

Mechanical deformations in a tunnel can present a significant safety hazard particularly during construction work on the tunnel itself or in its immediate surroundings. It is essential to quickly check the stability and reliability of the structure.

When choosing the sensor technology to be used for tunnel monitoring it is necessary to consider the following challenges:

- Will the sensors be able to reliably provide the required signal throughout the intended time – both in the short term and in the long term?

- Long cables are usually used in tunnels. Can you, therefore, guarantee the quality of the measurement signal even over long distances?

- Can the monitoring system be installed, without affecting traffic in the tunnel?

- And, of course, the fundamental question: what measurement quantities and underlying models are suitable, for example, to trigger an alarm in the event of a problem?

For all the above, optical sensor technology, based on fiber Bragg technology, has developed into a powerful alternative to conventional monitoring systems.