The HUBER + SUHNER RADOX® cables and their use in HPC high power charging system

In charging stations, cables and cable connections are exposed to strong vibrations, extreme temperatures, and aggressive fluids throughout their lifetime. There are rather high demands of the quality, longevity and temperature resistance of the cables and systems used. RADOX® multicore cables have high resistance and resistance to heat. They have been specifically developed for the construction of compact and lightweight high-performance equipment.

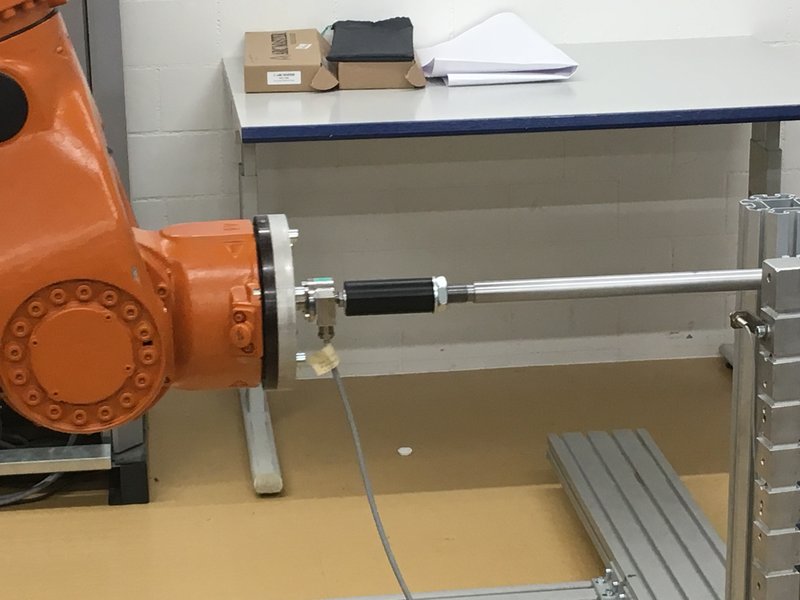

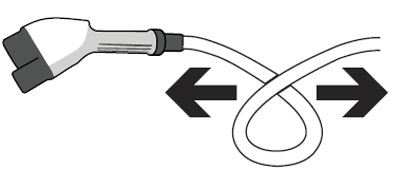

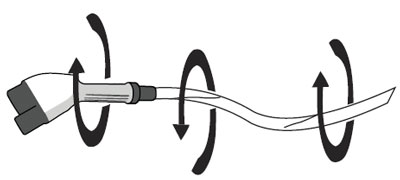

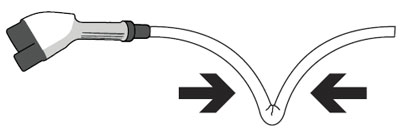

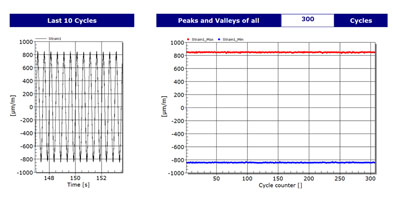

To ensure continued use in electrical charging stations, the cables are tensioned for testing in a torture bench and subjected to millions of load cycles.