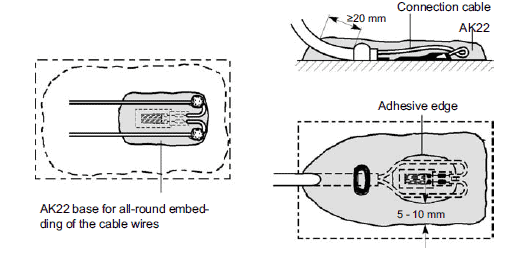

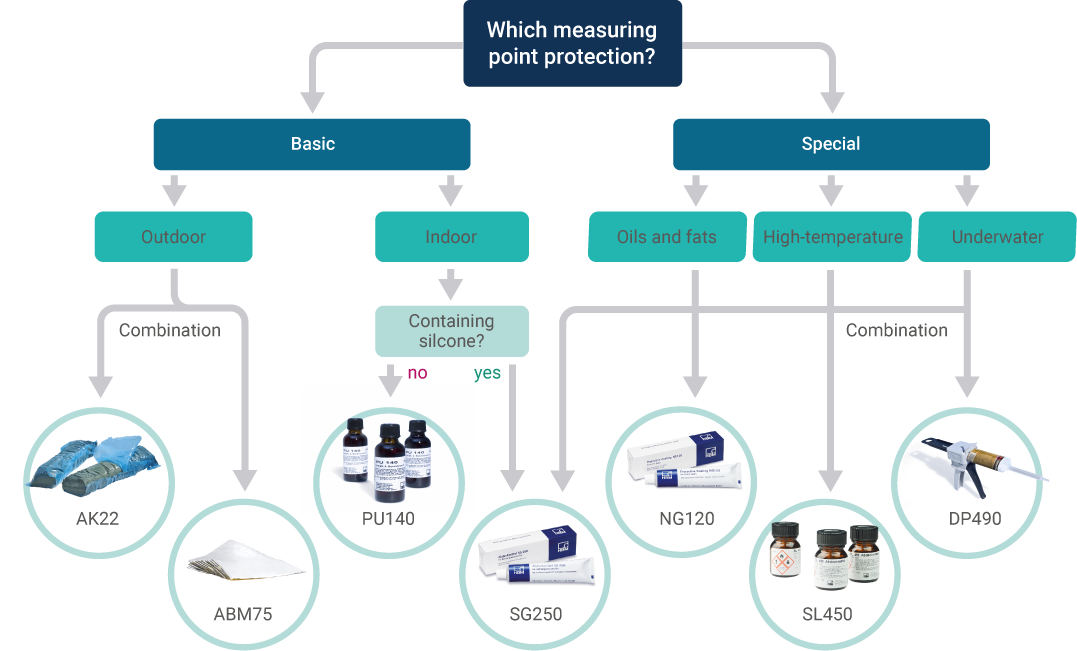

| AK 22 Viscous putty

Ord. no.: 1-AK22 | ABM 75 Aluminum foil with kneading cmpd

Ord. no.: 1-ABM75 | NG 120 Nitrile rubber

Ord. no.: 1-NG120 | SG 250 Transparent Silicone rubber

Ord. no.: 1-SG250 | PU 140 Polyurethane paint

Ord. no.: 1-PU140 | SL 450 Transparent silicone resin

Ord. no.: 1-SL450 |

| Temperature range of resistance in air in °C | -30°C...+75°C

[-22°F ... +167°F] | -196°C … +75°C

[-321°F … +167°F] | -40°C ... +120°C

[-40°F … +248°F] | -70°C … +200°C

[-94°F … +392°F] | -40°C … +140°C

[-40°F … +284°F] | -50°C … +450°C

[-58°F … +842°F] |

| Package contents | 1 kg | 11 pcs.

205 mm x 100 mm | Tube

with 150 g | Tube

with 85 g | 3 bottles

each with 30 ml | 3 bottles

with 25 g each |

| One Package sufficient for approx. | 30 SG | 200 SG | 200 SG | 20 SG | 250 SG | 90 SG |

| Application method | Kneading by hand | Pressing on by hand | Application from tube | Application from tube | Brush application | Brush application |

| Curing conditions | – | – | Air drying at room temperature | Room temperature | Room temperature

… + 80°C | In temperature levels from 95°C - 315°C |

| Storage life at room temperature | 2 years | 2 years | 15 months | 6 months | 9 months | 6 months |

| Ingredients | Viscous, kneadable, sticky putty | 0.05 mm thick aluminum foil coated with 3 mm thick kneading cmpd. | Brown, solvent one-component silicone rubber | Transparent, solvent free one-component silicone rubber | Solvent-containing one component polyurethane paint | Transparent, solvent-containing silicone resin |

| Weather | yes | yes | yes | yes | yes | yes |

Water:

Pressurized water

Condensation

Tropical climate

Water vapor | yes

-

-

-

no | yes

-

-

-

condtl. | yes

-

-

-

no | yes

-

-

-

no | yes

-

yes

yes

no | yes

-

-

-

no |

Oil:

Engine oil (RT/70°C)

Mineral oil (RT/70°C)

Hydraulic oil (RT/70°C) | no

-

-

- | no

-

-

- | yes

yes

yes

yes | yes

-

-

- | yes

-

-

- | -

-

-

- |

| Greases | - | - | - | - | yes | - |

| Solvents in general | no | condtl. | condtl. | no | - | condtl. |

Fuels:

Gasoline

Kerosene | no

no

– | no

no

– | yes

yes

yes | no

no

– | –

–

– | –

–

– |

| Aromatic / Aliphatic mixtures | – | – | condtl. | – | – | – |

Aromatics:

Benzene

Toluene

Xylene | no

–

no

no | no

–

no

no | condtl.

no

condtl.

condtl. | no

–

no

no | no

–

–

no | no

–

no

no |

Chlorinated solvents:

Dichloromethane

Carbon tetrachloride

Perchloroethylene

1.2-Dichloroethane

o-Dichlorobenzene | no

no

–

–

–

– | no

no

–

–

–

– | no

no

no

no

no

no | no

no

–

–

–

– | no

no

–

–

–

– | no

no

–

–

–

– |

Alcohols:

Ethyl alcohol

Methyl glycol

Butyl alcohol

Isopropyl alcohol

Ethylene glycol | condtl.

condtl.

–

–

–

– | yes

yes

–

–

–

– | condtl.

condtl.

no

condtl.

condtl.

yes | condtl.

condtl.

–

–

–

– | no

no

–

–

–

– | yes

yes

–

–

–

– |

Ketones:

Acetone

Methyl ethyl ketone | condtl.

condtl.

no | condtl.

condtl.

no | no

no

no | no

no

no | no

no

no | condtl.

yes

condtl. |

Terpenes:

Dipentenes

Turpentine | –

–

– | –

–

– | condtl.

condtl.

yes | –

–

– | –

–

– | –

–

– |

Acids:

Hydrochloric acid conc.

Sulfuric acid 50 %

Acetic acid 50 %

Nitric acid 50 %

Oleic acid conc.

Lactic acid conc.

Air containing acids | no

no

no

no

no

–

–

– | condtl.(1)

–

–

–

–

–

–

– | condtl.

condtl.

–

no

no

–

condtl.

– | yes

yes

yes

yes

yes

–

–

– | no

no

no

no

no

–

–

yes | yes

yes

yes

condtl.

yes

–

–

– |

Alkalis:

Sodium hydroxide 10 %

Potassium hydroxide 10 %

Ammonia 28 %

Air containing alkalis | condtl.

condtl.

–

–

– | condtl.(1)

–

–

–

– | condtl.

no

no

condtl.

– | no

no

–

–

– | condtl.

no

–

–

yes | yes

yes

–

–

– |

| Liquefied gases (excluding oxygen) | - | - | yes | - | - | - |

| UV resistance | yes | yes | yes | yes | yes | - |