Determining the root cause of motor failures

Monitoring power for an extended period on an inverter-driven system can be difficult due to the required sampling rate needed to accurately measure electrical parameters. Even inverters with switching frequencies as low as 8kHz will require sample rates above 100kHz to accurately measure their electrical values. This high frequency information can also contain an overwhelming amount of data if continuously monitored and recorded. For this reason, many extended monitoring tests can sample at a lower sampling rate and use calculated values to monitor and trigger temporary high speed acquisition. Potential calculated values to monitor include RMS, Power, Total Harmonic Distortion (THD), individual harmonic monitoring, and other values like Id or Iq.

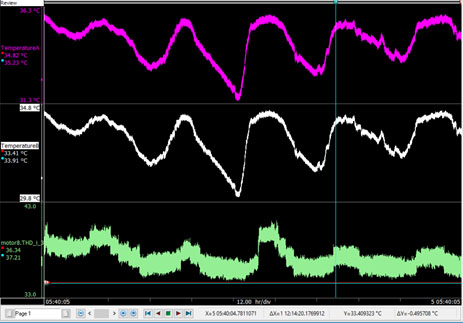

These time averaged values can give a significant amount of information about what is happening in the system while avoiding creating a significant amount of data. These measured values will be proportional to the fundamental frequency and will often be in the 100’s of Hz range which will significantly reduce data while providing excellent information on system behavior. Examples of information taken from monitored signals include the following:

- RMS values can show long term, or sudden changes inthe amount of voltage or current consumed.

- Power consumed can show if the operation of a system is drastically changing over time.

- Efficiency can show if the system is experiencing additional losses over time.

- THD is a leading indicator for failures.

- Individual harmonics can give more information on the nature of a failure.

- Control variables can show if current is shifting from useful torque to other parts of the system.