Until now, hydraulic test benches were designed for special tasks or products. Although the individual components are already tested, the interaction between individual pumps and control systems can only be tested in the machine of the user.

A new universal test bench for hydraulic drives will change all this: This test bench also tests the complex interaction of the individual components. The complete measurement chain from HBM, including the QuantumX amplifier, guarantees safe and reliable results.

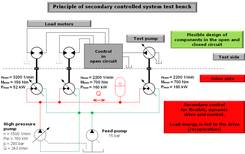

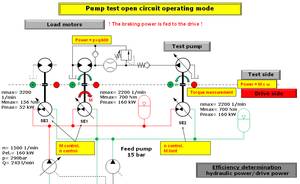

A special universal hydraulic test bench was custom-built, initiated by the wishes of the hydraulic system supplier HANSA-FLEX, conceived by the International Hydraulic Academy (IHA), designed and built by adt-Rinck, equipped with secondary controlled drives from Bosch Rexroth and modern measurement technology from HBM.

This test bench can examine complete hydraulic systems with different configurations instead of individual components. In close cooperation with the IHA, adt-Rinck acted as the general contractor and supplied the complete test bench turn-key. This joint project is now set up and working successfully in the R&D department of the IHA in Dresden-Weixdorf.

The adt-Rinck GmbH is an innovative company in the sector of special purpose engineering, bringing automation and information technology (IT) closer together. The company, founded in 1999, develops and produces industrial data-intensive automation systems.

The individual products such as test benches, software controllers, comparison or diagnostic systems bridge the gap between classic automation and modern IT worlds, acquiring, storing and processing process and production data (for instance, in the mass production of hydraulic components or in the automotive industry).

Specially developed hardware and software solutions for the evaluation and administration of technical and logistical data supplement or replace commercially available systems.