Vehicle Dynamics, Brakes (ABS, ESP), Tyres, Advanced Driver Assistance (ADAS)

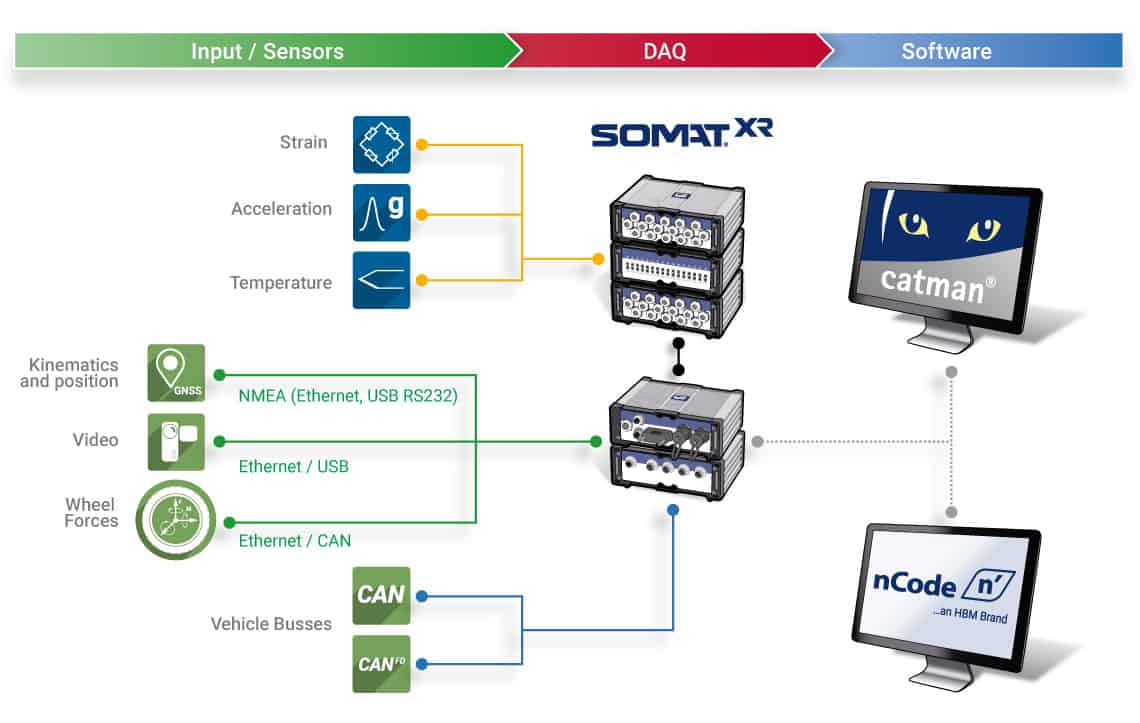

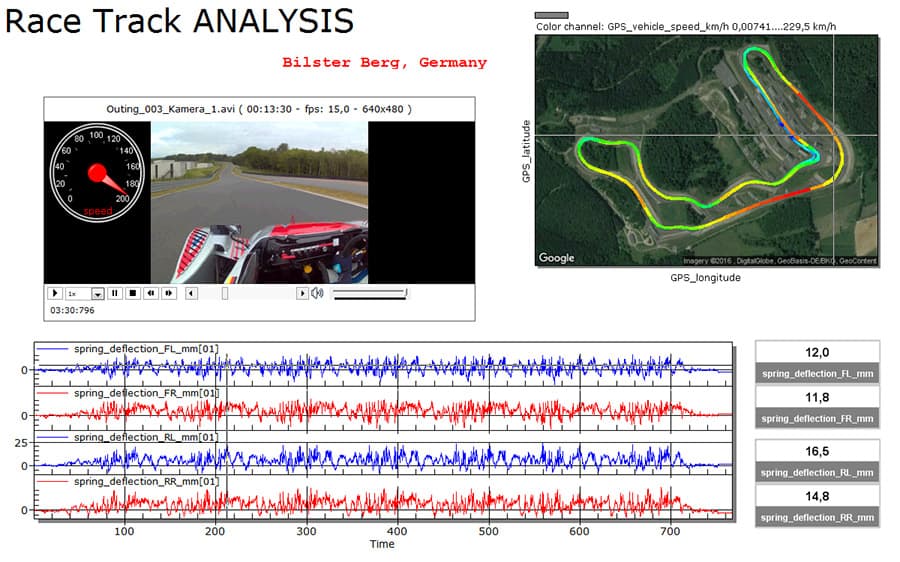

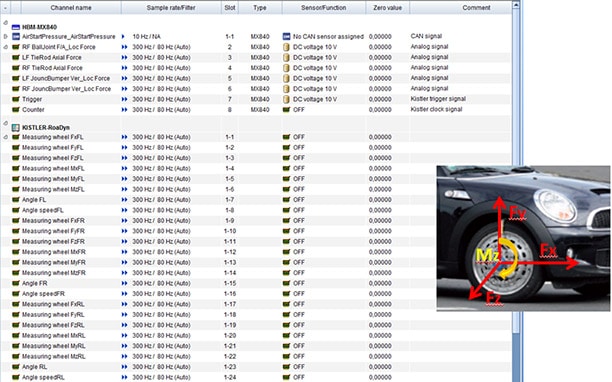

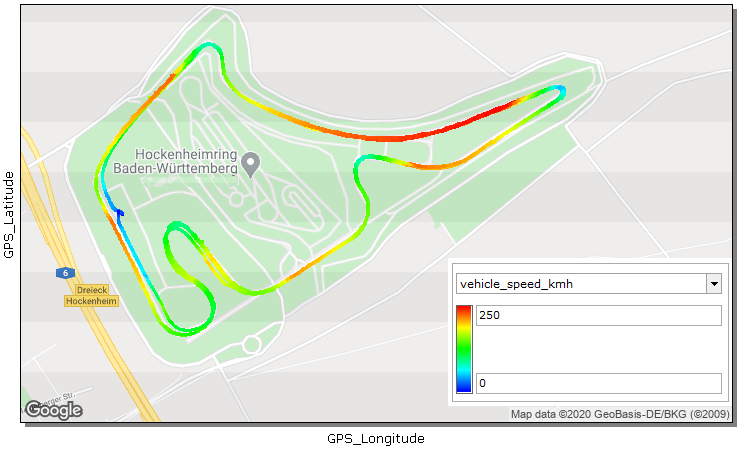

Vehicle dynamics testing deals with the investigation and analysis of the vehicle in motion, its ride and handling, economy, comfort, and safety attributes. It includes measuring the inertial kinematics of the vehicle, wheel forces, displacement and height sensing and vehicle bus data.

All kinds of longitudinal, lateral, and vertical dynamics are captured. Many of the test scenarios and manoeuvres are standardized by ISO and SAE test procedures ensuring repeatability and traceability including step steer, sinusoidal steering, lane change, brake tests and many more.

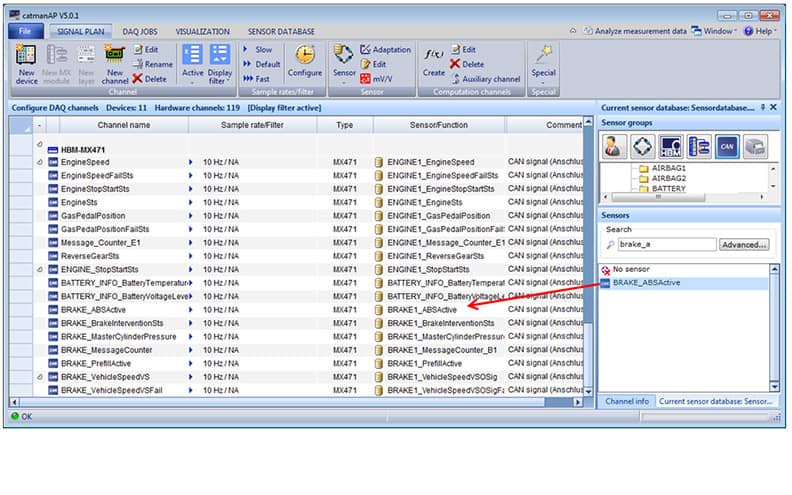

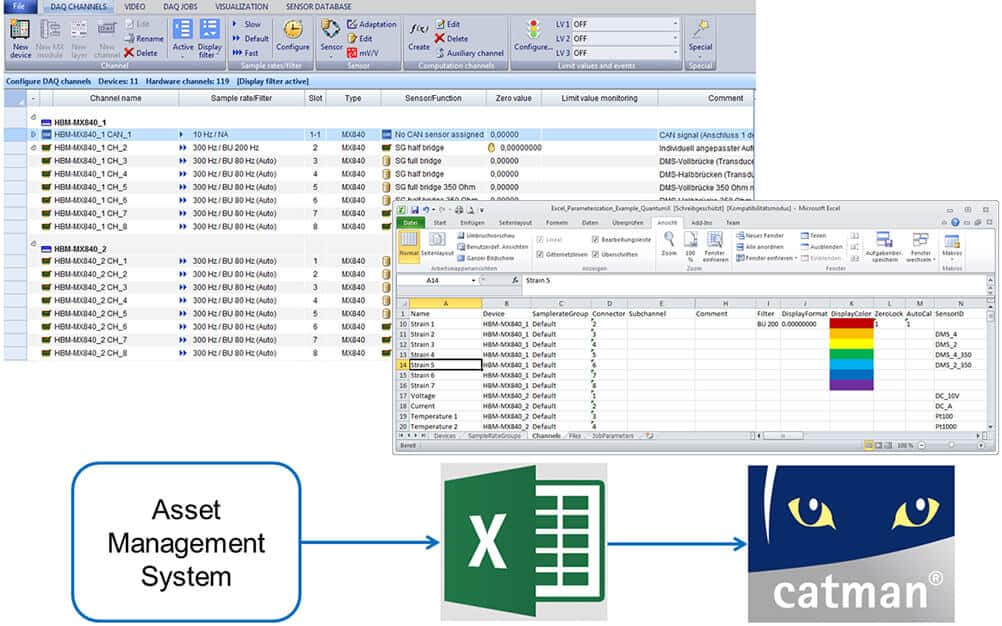

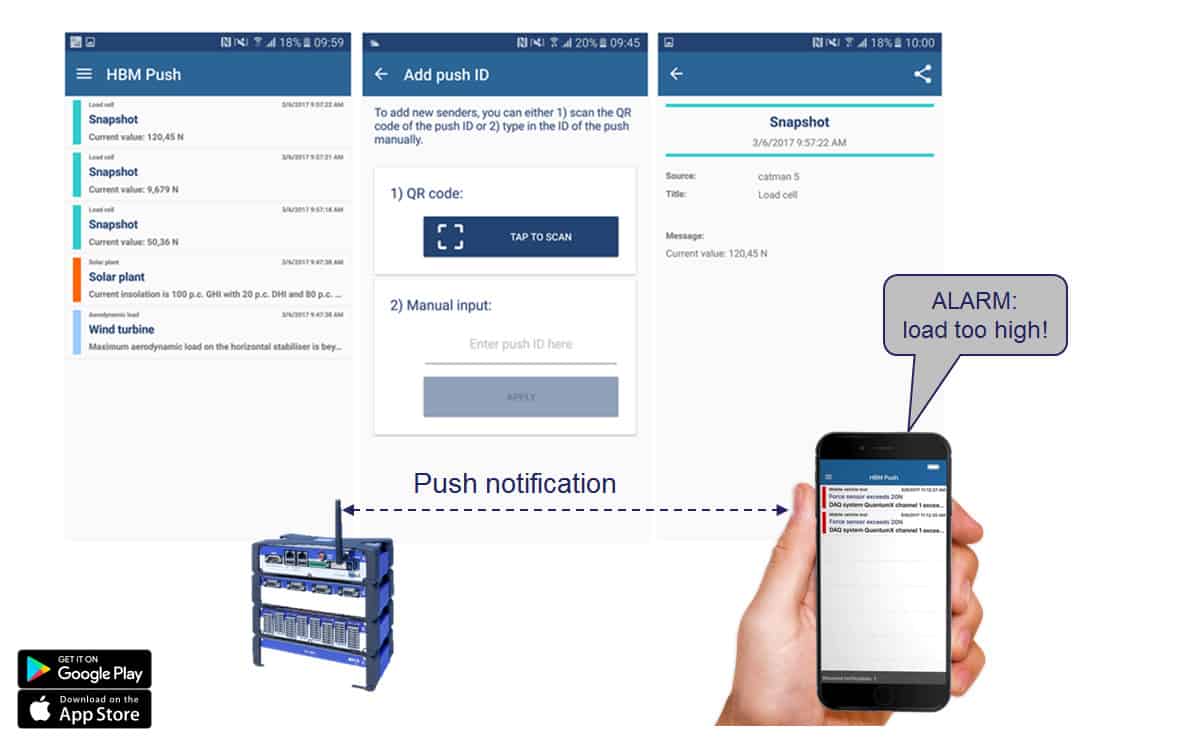

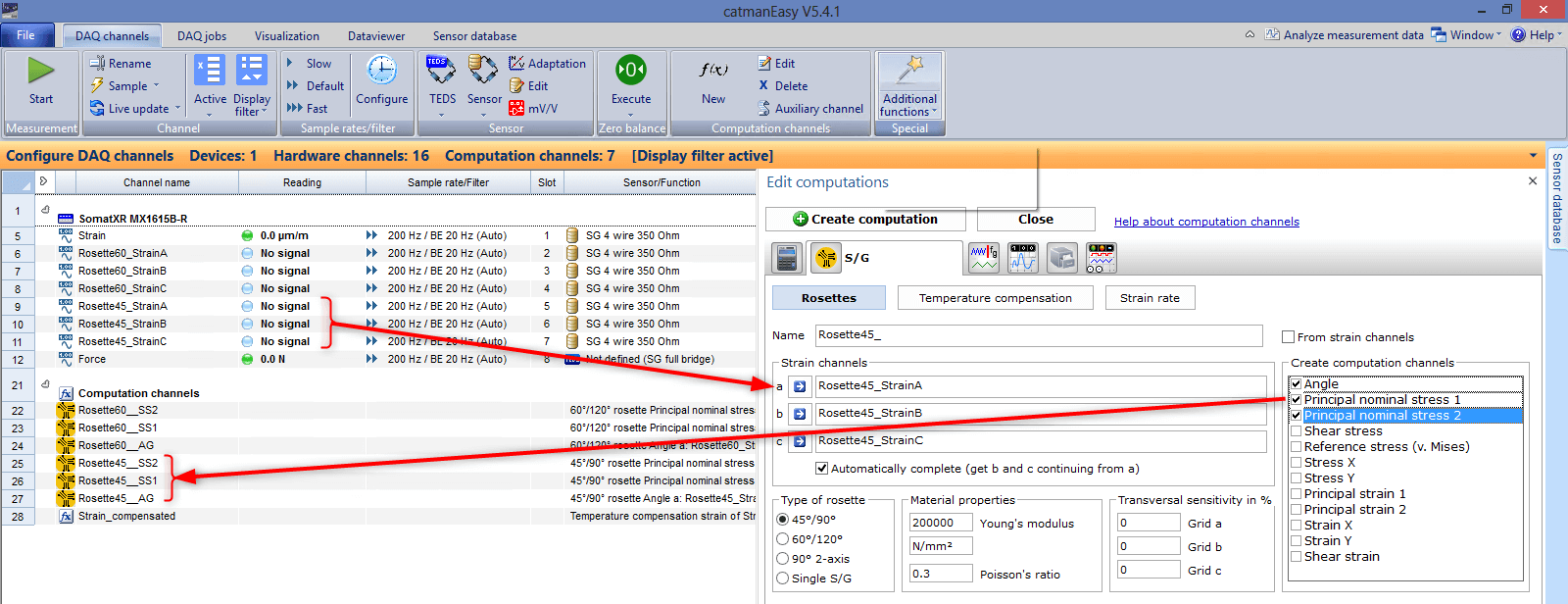

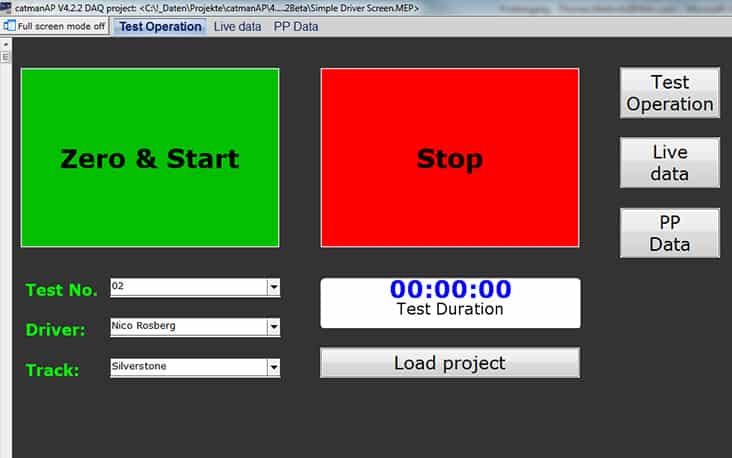

The tests are carried out by test drivers guided by their DAQ recorder and its script-based software or driving robots, automating the test scenarios. Often, these tests are used to investigate and optimize electronics and its functional software combined with homologation tests. Test results of the overall vehicle dynamics are also used to valid simulation models.