An explanation of the significance of ISO fits to standard shafts and holes

Correct torque application to the transducer is crucial for measuring torque. It is the only way to obtain precise and reliable measurement results.

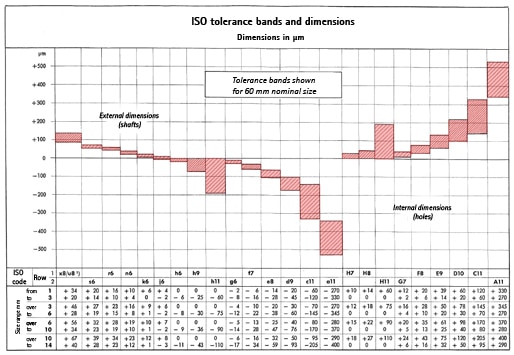

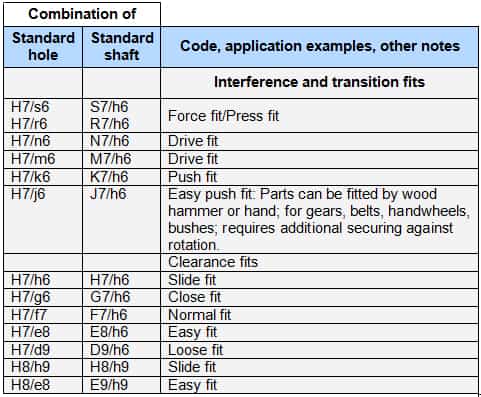

Torque is applied mainly via flanges using a friction joint, a method that has proven its worth a thousand times over with torque flanges, for example T12. Here a choice has to be made between ease of mounting through loose running fits or small unbalance through minimal clearance.

In many cases, no flange is available at the customer side, but instead a shaft stub. In this case, choosing the right fit is extremely important. It is the only way to ensure correct torque introduction with dynamic processes, too.