Cost advantages over other methods of force measurement, especially for large forces.

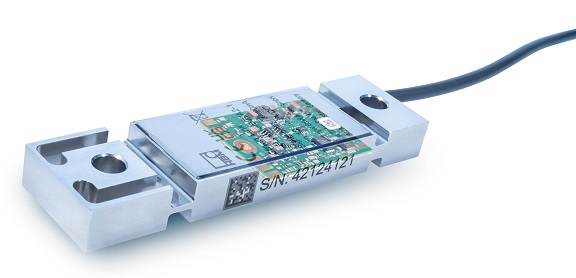

Strain transducer SLH700 – Hermetically sealed and with minimal influence on the measured object allowing use for lower strain to force comparatives

Extensometers, such as the SLH700 series measure forces indirectly and are distinguished by their simple yet effective functionality. When a force is applied to the structure on which the sensor is mounted, deformations whose magnitude depends on the applied force, occur. Therefore, even large forces can be measured with economically once the SLH700 has been calibrated.

SLH700 strain links are made from stainless steel materials, are hermetically sealed and have a high degree of protection (IP68). Their cable is resistant to most oils and many other potentially aggressive fluids. The transducer is built as a strain transformer. Therefore, the output signal is six times that of the single strain gauge.

The SLH700 strain link series can be purchased with or without an integrated amplifier, providing a selection of analogue output signals. All variants have an extremely low force shunt and can easily be mounted, requiring only two standard M6 screws.

- HBM accuracy class: 0.5

- Nominal (rated) measurement ranges: 500 µm/m

- Outputs: 1,5 mV/V, 0... 10 V, or 4... 20 mA, depending on variant

- Degree of protection: up to IP68

Economic measurements

- Inexpensive yet reliable – especially when measuring large forces

- The SLH700VA with integrated electronics and standard analogue outputs provides a particularly cost-efficient solution

For monitoring or manufacturing tasks

- Easy mounting with two M6 screws

- Oil resistant and highly flexible cable, suitable for drag chains

- High degree of protection (IP68); also suitable for permanent outdoor use

Robust and long-lasting force measurement even in unfavourable environmental conditions.

The complete package

- HBK supplies the sensors required for the calibration of the SLH700 strain link

- A service team can calibrate the measurement chain for you if required

Contact us to discuss a comprehensive and cost-effective solution for your measurement task.

Flexible for different applications

- Extremely low restoring force

- No impact on the stiffness of the system

The SLH700 is suitable for use on both large and delicate structures.

SLH700 CAD Step files

| Download the CAD step files for this product! | ||

|---|---|---|

| SLH700 CAD step files |

Benefits of the SLH700 strain link for typical applications

Simple calibration of the SLH700VA with integrated amplifier

To be able to provide the maximum possible output signal at any time and avoid measurement problems caused by noise or components with a low resolution, the SLH700VA has to be calibrated/adjusted after mounting. This can be quickly and simply achieved with a simple teach-in procedure.

Many available strain transducers with an integrated amplifier module only have a fixed amplification. This means that 500 µm/m, for example, correspond to an output signal of 10 V. The fundamental drawback of this method is that the maximum output signal depends upon the given amplification, which cannot be changed. If, in the example above, a strain of 200 µm/m is utilized as the input signal, the resulting output voltage is 4 V, which leads to unsatisfactory results, if the next element in the measurement chain is a module that has a low resolution or increased noise.

SLH700VA strain links with integrated amplifier electronics manage to bypass this problem, since they provide the maximum possible output signal at any time, independent of the intended purpose.

The teach-in procedure is simple:

- First, the sensor is installed in the usual manner, and the load on the machine (press, roll stand, silo) is reduced to zero. A longer pulse sent to the teach-in input is sufficient for the electronics to memorize the zero point.

- Subsequently, the calibration load is applied, sending another pulse (this time, a SHORT one) to the teach-in input, which is sufficient. Now, the electronics are adjusted between these two points.

- This enables the input range of the next level to be fully utilized at any time.

- The teach-in procedure can be performed at 25 %, 50 %, or 100 % of the full scale.

- There is always a buffer of 10% in the upper and lower parts of the measuring range. Higher strain signals (for example, in the event of a failure) are amplified and transmitted.

- The characteristic curve can also be negative. Both elongation and shortening can be converted into a positive signal.

- The built-in measuring amplifier provides low noise and a bandwidth of 2 kHz.

- It is essential to permanently store the span, that is, the difference between the minimum and the maximum. Therefore, it is imperative to reset to zero after a power failure.

SLH700 Product Literature

| Titolo / Descrizione | Lingua | Prodotti | Lingua | Tipi di contenuto |

|---|---|---|---|---|

| Data Sheets | ||||

| SLH700 - Caractéristiques techniques | French | |||

| SLH700 - Data Sheet | English | |||

| SLH700 - Datenblatt | German | |||

| SLH700 - 數據表 | Chinese | |||

| Mounting Instructions | ||||

| SLH700 - Mounting Instructions | English, German, French, Chinese | |||

| Declaration of Conformity | ||||

| SLH700 - EU Declaration of Conformity | Multi lingua | |||