Get the right strain gauge for residual stress measurements – for any desired method for residual stress analysis.

RY: Strain Gauges for Residual Stress Analysis (Ideal for Hole Drilling Method)

Determining residual stresses in materials (e.g. during casting, welding and forming processes) becomes easy with HBM's special strain gauges. These special strain gauges for residual stress analysis are available for precise and safe high-speed drilling (in combination with the MTS3000 drilling device from our partner company Sint Technology). For high-speed drilling, we also offer our patented six-wire strain gauges, which can compensate for non-centric boreholes, providing increased measurement accuracy.

- Supported residual stress measurement methods: integral hole-drilling, high-speed drilling

- Nominal resistance: 120 Ohm

- Measuring grid lengths: 1.5 to 5 mm

Versatility in Usage

- Ideal choice for residual stress analysis using hole-drilling method

- Additional strain gauge types for high-speed drilling available

- Select between eight different geometries for different methods and applications

Quick Installation

- Integrated measuring chain available for high-speed drilling (from our technology partner), including control and evaluation software

- Patented self-compensating strain gauge rosettes for high measurement accuracy in high-speed drilling

- Suitable accessories for quick and clean installation of the strain gauges on the measuring point

Fast and fail-safe installation of strain gauges. Residual stress measurements as simple as the application of "classical" strain gauges.

Fast Delivery

- Most types available directly from stock

- Comfortable ordering via the HBM online shop (available in many countries worldwide)

Get immediate results thanks to quick delivery. No delays for your measurement projects.

RY Technical Features

| Types available

| Nominal resistance

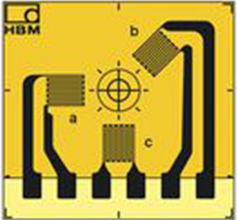

| Dimensions [mm/inch] | Solder Terminals

| |||

Measuring grid | Carrier | ||||||

[Ω] | a | b | c | d | |||

| 1-RY21-3/120 | 120 | 3 | 2.5 | - | 22.1 | LS 5 |

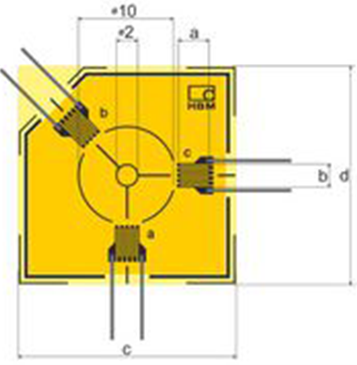

Types available

| Nominal resistance

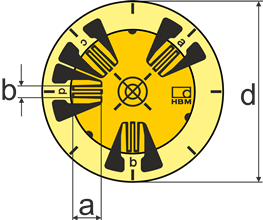

| Dimensions [mm/inch] | Solder Terminals

| ||||

Measuring grid | Carrier | ||||||

[Ω] | a | b | c | d | |||

| 1-RY61-1.5/120K | 120 | 1.5 | 0.8 | 7.2 | 12 | LS 7 |

| Types available

| Nominal resistance

| Dimensions [mm/inch] | Solder Terminals

| |||

Measuring grid | Carrier | ||||||

[Ω] | a | b | c | d | |||

| 1-RY61-1.5/120R | 120 | 1.5 | 0.8 | 8 | 13.5 | LS 7 |

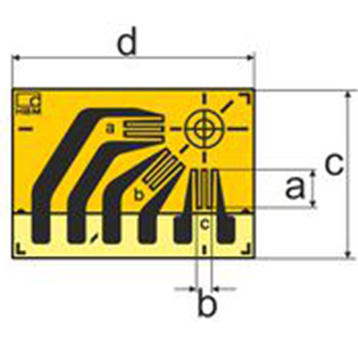

| Types available

| Nominal resistance

| Dimensions [mm/inch] | Solder terminal | |||

Measuring grid | Measuring grid carrier | ||||||

[Ω] | a | b | c | d | |||

| 1-RY61-1.5/120S | 120 | 1.5 | 0.8 | - | 10.2 | LS 5 |

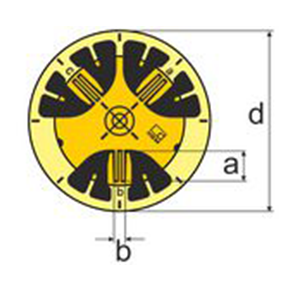

| Types available

| Nominal resistance

| Dimensions [mm/inch] | Solder terminal | |||

Measuring grid | Carrier | ||||||

[Ω] | a | b | c | d | |||

| 1-RY61-3.2/120S | 120 | 3.2 | 3.2 | 20.9 | 22 | LS 5 |

| Types available

| Nominal resistance

| Dimensions [mm/inch] | Solder terminal | |||

Measuring grid | Carrier | ||||||

[Ω] | a | b | c | d | |||

| 1-VY61-1.5/120S | 120 | 1.5 | 0.8 | - | 10.2 | LS 5 |

Product Literature

| Title / Description | Language | Products | Language | Content Types |

|---|---|---|---|---|

| Data Sheets | ||||

| Dehnungsmessstreifen - Katalog | German | |||

| Strain Gauges - Catalogue | English | |||

| Тензорезисторы - катало́г | Russian | |||

| Declaration of Conformity | ||||

| Strain Gauges and Accessories - Statement of Compliance | English | |||

| Tech Notes | ||||

| Determine the thermal expansion coefficient | English | |||

| Wärmeausdehnungskoeffizient bestimmen | German | |||