DSE-HIE: Future-Proof, EHEDG-Compliant Sensor Electronics

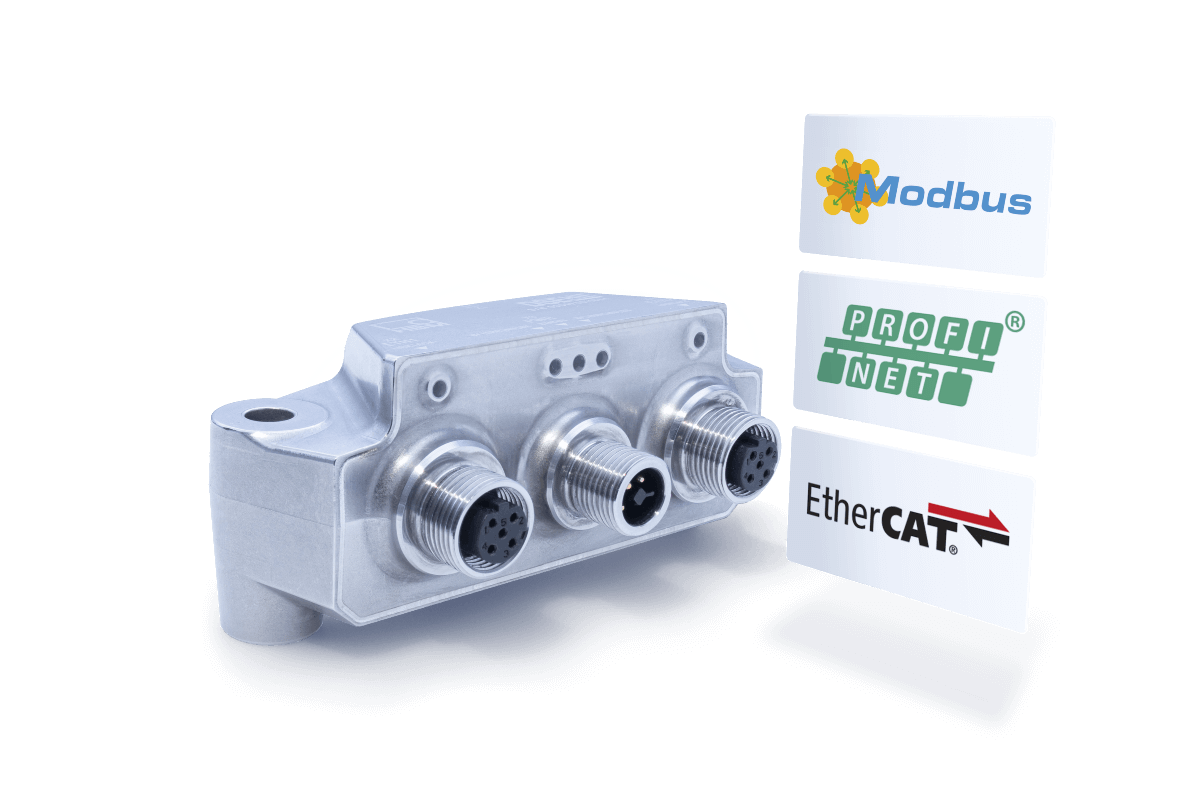

The innovative Digital Sensor Electronics (DSE) is ideal for use in highly dynamic and automated weighing and industrial automation applications. The signals provided from analog strain gauge-based sensors such as load cells and force transducers are digitized and can be output in line with all common industrial Ethernet protocols (PROFINET RT/IRT and EtherCAT and Modbus/TCP) via the integrated multi-protocol unit. The Ethernet interface and simple installation close to the sensor allow for time-efficient integration. The standardized CiA 461 command set further reduces the time required to get the system up and running. An intuitive web interface facilitates both the parameterization and the acquisition of measured values, making any additional software unnecessary.

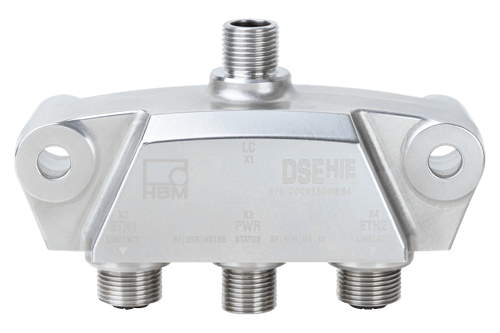

The DSE is housed in a compact stainless-steel enclosure. Its hygienic EHEDG-compliant design allows its use in applications requiring the most stringent hygiene and cleanliness standards, such as in the food and beverages, pharmaceutical-, in industrial process- and factory automation. Owing to its IP67/68/69K degree of protection, the device is optimally protected and can be cleaned with high-pressure cleaners or employing CIP (clean-in-place) systems.

Hygienic

- IP67, IP68, IP69K degree of protection (only with a connected plug)

- EHEDG compliant

- Certified by ECOLAB

For use in areas with rigorous hygiene requirements and in harsh industrial environments, especially in cold-aseptic applications

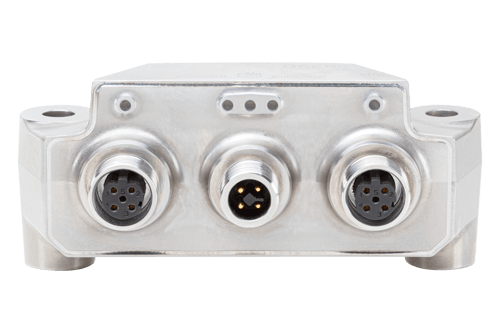

Communicative

- Support of PROFINET, EtherCAT, Modbus/TCP

- Parameterization and acquisition of measured values via integrated, intuitive web server using TCP/IP

- Optimized for daisy-chain wiring due to internal switch

Time saving Plug & Work solution for modern industry environments

Precise

- 10,000e for maximum accuracy, 0.01%

- 2,000 measured values per second

- Integrated filters for precise weighing and automation applications

Maximum output for retrofitting and new systems

New: Integrated Algorithms for Filling, Sorting, Checkweighing and Container Weighing

Optimize your processes: The new process algorithms can be easily parameterized via the integrated WebServer. The algorithms work in real time, relieve the machine control and ensure optimal results.

View and record processes in any detail, check via integrated frequency-analysis (FFT) and optimize your processes with algorithms for many Standard-scales, Filler- and Check-Weighing applications.

Think Hygiene and robust, Think HBM – The Ideal Measurement Chain for Your Application

The DSE weighing electronics means PROFINET for every strain gauge-based sensor. It also enables HBM to comply with rigorous hygiene requirements: Besides matching electronics, the portfolio also offers easy-to-clean and EHEDG-compliant load cells. The modular system comprises matching accessories that facilitate straightforward solutions while ensuring maximum cleanliness.

DSE Product images

DSE 3D CAD STEP Files

| Download the CAD step files for this product | ||

|---|---|---|

| DSE CAD step files |

Product literature

| Title / Description | Language | Products | Language | Content Types |

|---|---|---|---|---|

| Data Sheets | ||||

| DSE-HIE - Caractéristiques techniques | French | |||

| DSE-HIE - Data Sheet | English | |||

| DSE-HIE - Datenblatt | German | |||

| DSE-HIE - Folha de dados | Portuguese | |||

| DSE-HIE - Hoja de características | Spanish | |||

| DSE-HIE - Prospetto dati | Italian | |||

| DSE-HIE - 데이터 시트 | Korean | |||

| DSE-HIE - データシート | Japanese | |||

| DSE-HIE - 數據表 | Chinese | |||

| Operating Manuals | ||||

| DSE - Operating Manual | English, German | |||

| Declaration of Conformity | ||||

| DSE-HIE - EU Declaration of Conformity | Multilanguage | |||

| Device Descriptions | ||||

|

DSE ESI-files (EtherCat)

DSE device description file for EtherCAT. Date: 05/2023 | Size: 2 KB | Multilanguage | |||

|

DSE GSDML file (ProfiNet)

DSE device description file for PROFINET RT and IRT. Date: 05/2023 | Size: 8 KB | Multilanguage | |||

| Firmware | ||||

|

DSE-HIE Firmware and WebServer

Archive including all current files for firmware and DSE WebServer. To update firmware and WebServer the existing WebServer in the DSE-HIE can be used (no additional software or hardware needed). Date: 05/2023

|

Version: 3.1.0

|

Size: 2 MB

| Multilanguage | |||

| Software | ||||

|

Automation-API WINDOWS Library and Software-Example

The HBM Automation API (Application Programming Interface) is an opensource interface that allows to access the functionality of various devices via Ethernet, WTX110, WTX120 and DSE-HIE. This enables to quickly create own application programs optimally adapted to your applications. It includes the links to download the API from GIT-HUB github.com/HBM/Automation-API , a detailed manual with How-To´s and Ready-made examples to get started in only minutes with MS-Visual-Studio, also an EXE-Example to connect and operate DSE and WTX devices without software-environment. Legal notice: The code and example does not imply any warranty or guarantee. Date: 02/2021 | Version: 1.0 | Size: 453 KB | Multilanguage | |||

|

DSE CAE data for ePLAN Electric P8

Macro-project containing CAE data for ePLAN Electric P8. Date: 01/2021 | Version: 1.0 | Size: 22 MB | Multilanguage | |||

|

DSE Example Filler Project with Raspberry-PI PLC and codesys

This is a quick start guide for using the filler function of a DSE. This function serves the optimization and monitoring of processes. By means of a user-friendly interface, complicated control technology is available for every user. For initial commissioning, all you need is a computer, sensor and a DSE. This can be extended by a PLC, which takes over the values set in the DSE for fast and accurate control. In this example, a Raspberry PI Model 4B with Codesys as PLC is used with a PROFINET or EtherCAT interface. The functionality of the filler is available in DSE from the FW V2. 0. Legal notice: This example does not imply any warranty or guarantee. Date: 04/2022 | Version: 1.0 | Size: 55 MB | Multilanguage | |||

|

DSE Example Check-weigher Project with Raspberry-PI PLC and codesys

This is a quick start guide for setting up a checkweigher with the DSE (from FW 2. 0). The control scale can be controlled in two ways, on the one hand via a level and on the other via an external signal (in this example a pushbutton). The DSE has no hardware DIO’s, so the trigger signals are captured by a PLC and transmitted to the DSE, here a Raspberry Pi Model 4B with Codesys as PLC, with a PROFINET and EtherCAT interface. Legal notice: This example does not imply any warranty or guarantee Date: 04/2022 | Version: 1.0 | Size: 53 MB | Multilanguage | |||

|

DSE Example Checkweigher Project with Siemens PLC and TiA portal

This is a quick start guide for setting up a checkweigher with the DSE (from FW 2.0). The control scale can be controlled in two ways, on the one hand via a level and on the other via an external signal (in this example a pushbutton). The DSE has no hardware DIO’s, so the trigger signals are captured by a PLC and transmitted to the DSE, in this example by a Siemens S7-1200 PLC with TiA-portal, with a PROFINET interface. Legal notice: This example does not imply any warranty or guarantee. Date: 06/2022 | Version: 1.0 | Size: 5 MB | Multilanguage | |||

|

DSE Example Filler Project with Siemens PLC and TiA portal

This is a quick start guide for using the filler function of a DSE. This function serves the optimization and monitoring of processes. For initial commissioning, all you need is a computer, sensor and a DSE. This can be extended by a PLC, which takes over the values set in the DSE for fast and accurate control. In this example, a Siemens S7-1200 PLC with TiA-portal is used with a PROFINET interface. The functionality of the filler is available in DSE from the FW V2. 0. Legal notice: This example does not imply any warranty or guarantee. Date: 06/2022 | Version: 1.0 | Size: 6 MB | Multilanguage | |||

|

Ethernet Device Configuration Tool

Software tool for initial setting of the IP address for the DSE, as it has no default IP address in the delivery state. Date: 06/2020 | Version: 1.0 | Size: 6 MB | Multilanguage | |||

| Tech Notes | ||||

|

DSE Tech Notes

This is a collection of technical application reports for requirements around DSE.

Legal notice: The examples given are intended to illustrate the solution and integration into DSE. Date: 09/2022 | Size: 3 MB | Multilanguage | |||