FIT5A Digital Load Cell: The Heart of Weigh Fillers

Premium foods, too, are under increasing price pressure. For the manufacturers of filling machines this means that they need to ensure ever more precise filling to minimize overfill and increase output.

This requirement is met by using weigh fillers based on the FIT5A digital load cell. FIT5A is the result of over 10 years of close cooperation with the market leaders in this industry. Even the smallest detail of this load cell has been optimized for use in this type of machinery.

Specialized to perform batching tasks as well: Integrated filters and a filling algorithm make FIT5A the perfect candidate for batching tasks. It forms the heart of heavy-duty multi-head combination weighers or hopper scales.

- Confirmed precision: OIML certificate for C4, Y up to 25,000

- Maximum capacity: 5 kg ... 50 kg

- Slim design: Minimal space required in rotational fillers

- IP68/69K even at the connector: The perfect solution for moist climates and high-pressure cleaners

- Steel is food safe and resistant to strong detergents

- Integrated electronics allow for maximum precision. Hence: less overfill and more output.

Robust

- 1000% overload stability: Should it happen - the load cell even withstands cleaning crews stepping on it when working in a hurry

- High lateral force stability: Withstands rough handling of bottles

- Excellent off-center load behavior: Ideal for eccentric intake of bottles (eccentric load application)

- Connector instead of cable: Fast replacement in case of an emergency

Intelligent

- FIT5A is capable of autonomously controlling valves and thus taking over the entire filling process: No additional PLC is required

- Tried and tested filling algorithm providing many specialized functions (such as bottle breakage detection): Prepared for every filling and batching task

- Operation via free PanelX software: Saves valuable development time

1000% Overload Protection

...should it happen: The FIT5A even withstands cleaning crews stepping on it when working in a hurry.

CAD Drawings and CAD Models

Please click here to download CAD files

Please note: The CAD download is handled by a third-party company which requires a separate user registration.

2 variants available

- 1 connector - for use in combination with PLC

- 2 connectors - the load cell autonomously controls the filling head

Communication with the machine:

- Fieldbus support: RS485, CANopen and DeviceNet

You will find more information in the data sheet.

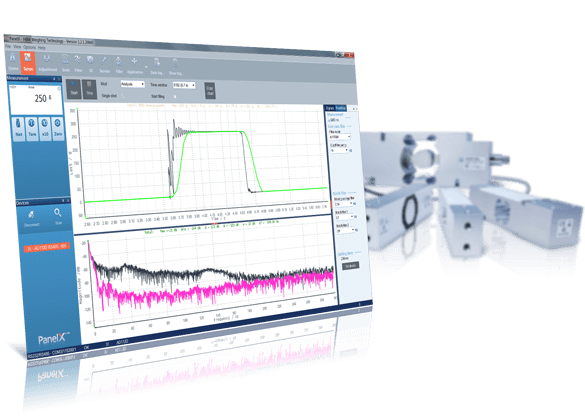

Configure, analyze, optimize filling processes using PanelX

PanelX is the cross-platform software from HBM that enables you to set up, configure and analyze your dynamic weighing technology applications.

Use PanelX to conveniently and intuitively configure and control the filling algorithm integrated with FIT5A.

PanelX analyzes parameters such as filling time and residual flow and supports you in optimizing the filling process.

Documents and downloads

| Title / Description | Language | Products | Language | Content Types |

|---|---|---|---|---|

| Data Sheets | ||||

| FIT5A - Data Sheet | English | |||

| FIT5A - Datenblatt | German | |||

| FIT5A - データシート | Japanese | |||

| Brochures | ||||

| Digital weighing technology solutions - Brochure | English | |||

| Digitale Wägetechniklösungen Broschüre | German | |||

| Operating Manuals | ||||

| FIT5A - Operating Manual | French, English, German, Italian | |||

| Accessories | ||||

| 1- KAB - データシート | Japanese | |||

| Cables and Connectors - Data Sheet | English | |||

| Câbles avec connecteur - Caractéristiques techniques | French | |||

| Kabel mit Stecker - Datenblatt | German | |||

| Certificates | ||||

| FIT5, FIT/5... - OIML Certificate | English | |||

| FIT5, FIT/5... - Test Certificate | English | |||

| FIT5A/PW15.../SP4M/PW25/PW37P/PW27A/PAD - Ecolab material resistance Certificate | English | |||

| Declaration of Conformity | ||||

| FIT5A - EU Declaration of Conformity | Multilanguage | |||

| Other | ||||

| AED / FIT - Application Note 012e: AED/FIT® Commissioning CANOpen | English | |||

| Device Descriptions | ||||

|

EDS Files

Date: 07/2023 | Size: 39 KB | Multilanguage | |||

| Firmware | ||||

|

WT Release Notes

Description of the AD104C + AD105C (both EOL) /AD105D / FIT5 + FIT7 and PAD firmware releases Date: 07/2023 | Size: 121 KB | Multilanguage | |||

| Software | ||||

|

PanelX

Panel software for:

Download, unzip and install the Tool on a PC with Windows 7/8/10/11 or 12. Date: 09/2023

|

Version: 2.2.0

|

Size: 26 MB

| Multilanguage | |||

|

PanelX WebHelp

WebHelp for PanelX in English and German language. Date: 03/2019 | Version: 2.0.6 | Size: 23 MB | Multilanguage | |||