Minimal assembly time and high operational safety during production, monitoring and test tasks.

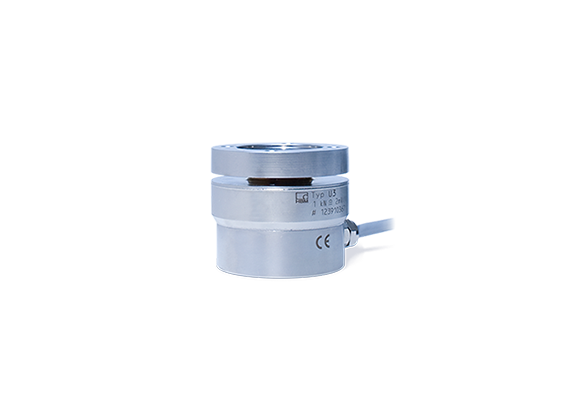

U3 Force Transducer: Capacities ranging from 0.5 kN to 100 kN

The U3 load cell is based on the diaphragm principle; which means the strain gauges are mounted within the load cell housing in a well protected manner. Due to the design of the supporting membrane, the U3 force sensor guarantees an exceptionally high lateral force stability of up to 100%.

The U3 has a bending moment adjustment, so that acting moments as well as transverse forces are largely compensated for. The robust design is combined with a double-sided flange connection. This allows the sensor to be mounted quickly (within a few minutes): this minimizes downtime in production. The accuracy exceeds the typical requirements in manufacturing applications.

- HBM accuracy class: 0.2

- Nominal forces: 0.5 kN to 100 kN

Practical

- Hassle-free mounting via flange with integrated centering points

- Can be easily connected to an electrical source

- Optional: Adapter for connecting knuckle eyes, as well as plug-in connectors and TEDS

Robust

- Exceptional lateral force stability thanks to special support membrane construction

- High torsional and bending moment stability

- Stainless steel design

- Standard at HBM: High immunity to electromagnetic fields

Proven reliability: Measurement results are immune to the effects of transverse forces, bending moments, torsion and electromagnetic fields.

CAD Step Files for U3 Force Sensors

| Download the CAD step files for this product | ||

|---|---|---|

| U3 CAD step files | ||

| U3 Accessories CAD step files |

Accessories Available

- Adapters for knuckle eyes

- Knuckle eyes

You will find more information in the data sheet.

U3 Product Literature

| Title / Description | Language | Products | Language | Content Types |

|---|---|---|---|---|

| Data Sheets | ||||

| U3 - Caractéristiques techniques | French | |||

| U3 - Data sheet | English | |||

| U3 - Datenblatt | German | |||

| U3 - Prospetto dati | Italian | |||

| Brochures | ||||

| Kräfte sicher messen - Broschüre | German | |||

| Reliable force measurement - Brochure | English | |||

| Mounting Instructions | ||||

| U3 - Istruzioni di montaggio | Italian | |||

| U3 - Mounting instructions | English, German, French | |||

| Declaration of Conformity | ||||

| U3 - EU Declaration of Conformity | Multilanguage | |||