Advanced Aircraft Electric System & Equipment Testing

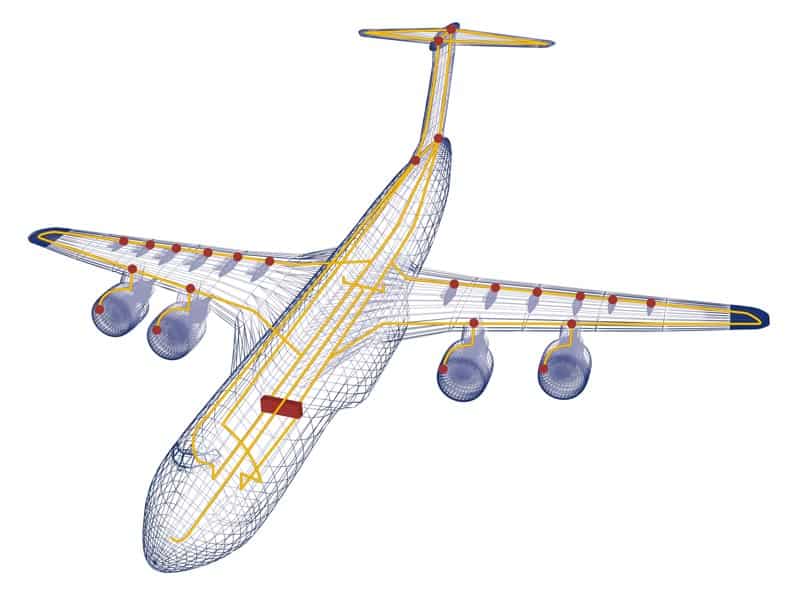

The electrification of an aircraft is driven by the vision of making airplanes for more efficient, less costly to operate, and more environmentally friendly in terms of exhaust gas and noise emissions. In order to transform today's conventional aircraft to the electric plane, hydraulic and pneumatic actuators and systems will gradually be replaced by electric actuators and systems.

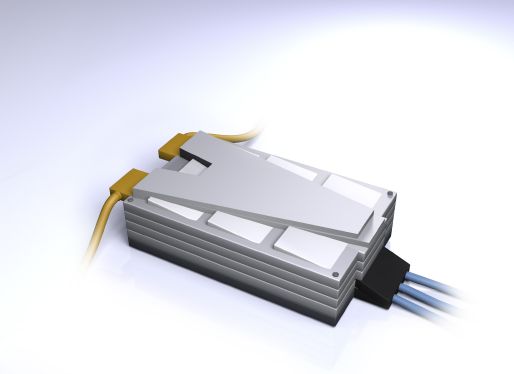

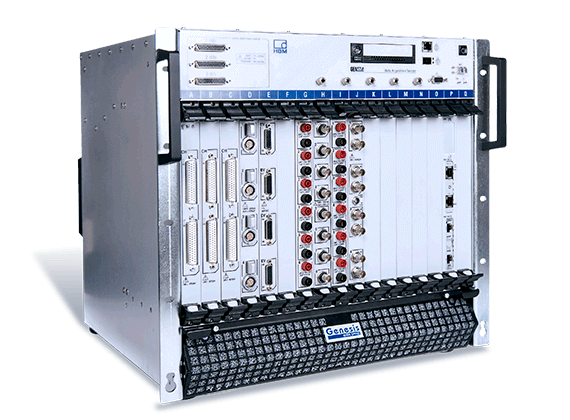

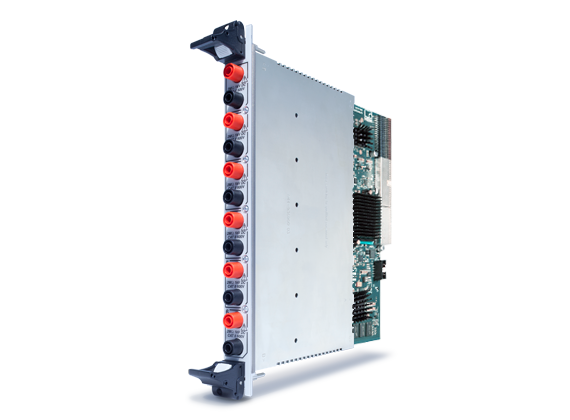

The main technological challenges to achieve these are to reduce the weight and increase the efficiency, power density and reliability of the components of the aircraft electric system, i.e. of the electric generators, batteries, power controllers and motors. Testing the energy conversion efficiency of these components requires data acquisition systems (DAQ) that are both able to measure aggregate input and output power with high accuracy and reliability and deliver the underlying raw data necessary to understand and improve energy efficiency in the R&D process.

As a consequence of electrification, it will become more challenging to ensure a stable operation of the aircraft electric system. Both, individual components as well as the entire aircraft electric grid will need to be tested more extensively for power quality compliance. DAQ systems for such tests need to be able to both continuously record the entire flight profile and switch to higher sample rates to capture singular disturbances. They should be able to perform both harmonic analysis and power measurements with the same instrument.