In-the-Line and End-of-Line

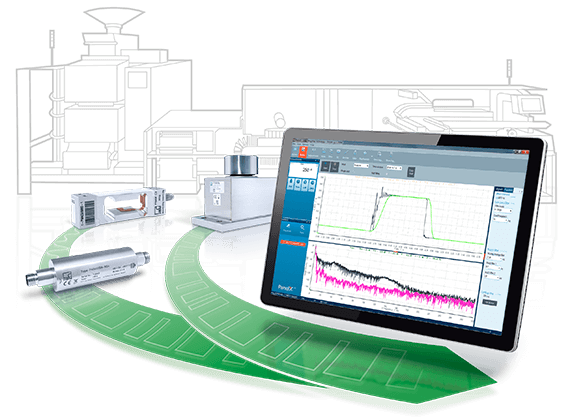

With flexible weighing technology from HBM you can choose between an In-the-Line solution or a multi-track application (serialization) and an End-of-Line solution.

The In-the-Line solution consists of a compact measurement chain with strain gauge load cells and plug&play electronics for smaller packaging units such as stick packs. This space-saving and high-precision solution ensures maximum system productivity.

The End-of-Line solution (aggregation) is suitable for larger packaging units such as cartons or pallets. It consists of a digital load cell with integrated electronics. Thanks to rugged, high-precision products you benefit from reduced downtimes of your machines, thereby increasing the overall availability of your systems.