Powerful plant operating and servicing tools.

Software, Application Programming Interfaces and Online Solutions for HBK’s Industrial Electronics

Just like HBK hardware, our software solutions adapt fully to your needs, offering state-of-the-art functionality, easy implementation, and maximum customization capabilities. Whether it’s off-the-shelf software or a modular programming kit, HBK offers a set of modern and smart solutions for visualization, parameterization, data acquisition, cloud connection and servicing.

Ready-to-use multifunctional PC software for production and weighing applications. Can be used for servicing and parameterization or for continuous plant operation.

Web-based visualizations for terminals, tablets, and smart devices in the form of an integrated web-server, a PWA or mobile apps. Modern ergonomic user interfaces with intuitive operation.

Operates on all browser-based devices, whether stationary or mobile.

APIs and drivers as a pre-made programming kit with templates for the creation of individual GUIs perfectly adapted to the application at hand.

Multifunctional human machine communication for high security of know-how and investment.

Frequently Asked Questions

Open automation means: make digitalization simple with the help of powerful and easy-to-use open software development kits (SDKs) for smart manufacturing. Applications from manufacturing and weighing technology such as checkweighing, controller functions or quality control can also be easily implemented.

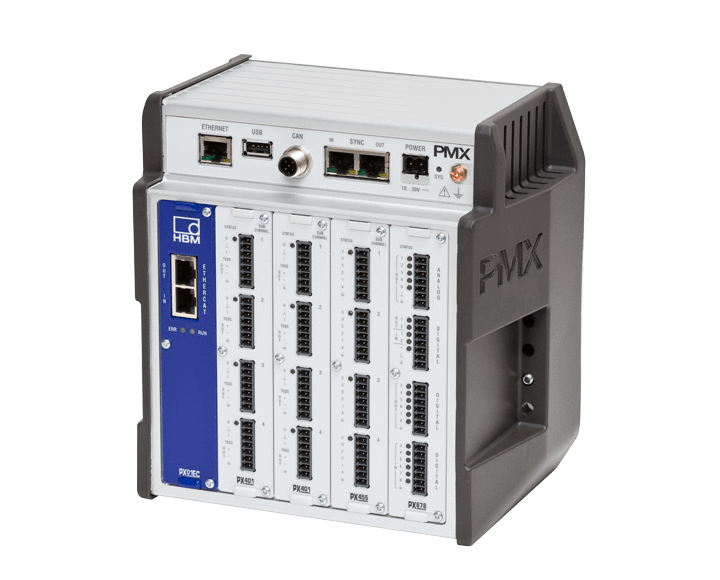

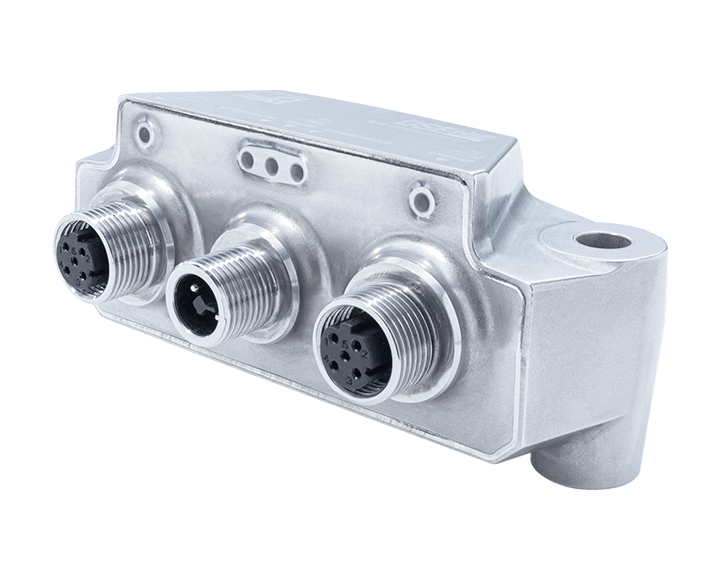

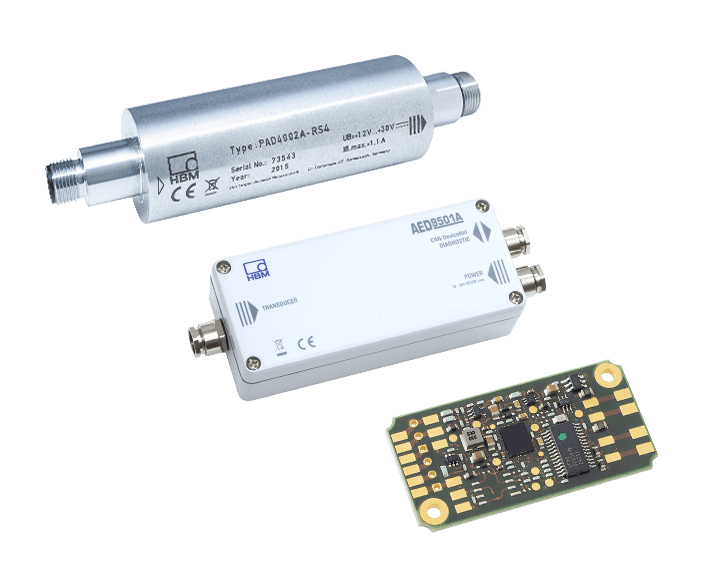

The use of smart sensors, load cells and smart measuring amplifiers is essential for the implementation of open automation. Intelligence must already be present directly in the component, for example in the form of "open interfaces" or "edge computing", to be able to process data efficiently and specifically.

Open source refers to software whose source code is made publicly available and can usually be used free of charge. It can be modified and enhanced, but in some cases, certain conditions will have to be observed.

The HBM Automation API can be modified and distributed freely. No license fees apply. However, the copyright and the permission notices have to be included in your software (see GitHub).

API stands for Application Programming Interface and refers to a programming interface that facilitates the creation of application programs. It is effectively a collection of functions that allows you to communicate between different components of a system without having to know the specific instructions. The API thus provides all the building blocks you need to communicate with devices when developing an application program.

WebSocket is a communication protocol designed for operation via the TCP port of the measuring amplifier. It allows bidirectional communication via a single TCP connection and thus enables interactive communication between a web application and the WebSocket server.

Modbus is a serial communication protocol and is considered the standard for communication with a PLC (Programmable Logic Controller). The Modbus protocol uses TCP port 502 by default. Jet or the Jet Bus (https://jetbus.io) is a framework (programming framework) designed for fast network communication, especially for IoT (Internet of Things). It uses publish/subscribe messaging that allows multiple clients to connect to a server. Jet communication is based on the TCP-based WebSocket protocol using the TCP device port.

The HBK Automation API uses Jet to enable you to efficiently create your own solutions via a 2-way encrypted TCP/IP connection. The required programming blocks for communication are already available in the API.

PLC interfaces such as PROFINET®, EtherNet/IP™ or PROFIBUS® only provide a standard for fieldbus communication. Therefore, the programming of the communication via these interfaces has to be done by the user.

Learn more:

Create Your Own Weighing Application Using the Open Source API

The recorded webinar demonstrates how to implement complex functions within your own programs. Learn about capability and requirements, how to create a simple weighing application using the IE API, and how to use this new application to connect to a weighing Indicator in the network via Wi-Fi.

Get Smart in Your Production and Save Time and Money

This recorded webinar teaches you how to optimize processes, reduce costs and expand productivity with the help of smart measuring amplifiers. Find out about hardware and software solutions in the context of the Industrial Internet of Things, and how to ensure interoperability through suitable protocols.

ClipX Software Integration

The video tutorial shows different options of data acquisition, visualization, and parameterization with ClipX. Choose whether you want to use the catman software, the ClipX webserver or LabVIEW and the API, and learn how to do the initial setup and getting things going.