XY Torsion/Shear Strain Gauges with 2 Measuring Grids for Measurements on Torsion Bars and Determining Shear Stresses

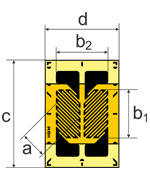

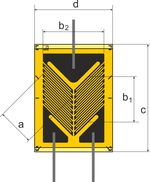

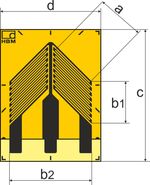

Types XY1, XY2 and XY4 are V-shaped strain gauges (SGs) with 2 measuring grids arranged at an angle of about 45° to the SG axis. Typical applications for these strain gauges include measurements on torsion bars and determining shear stresses as they occur in shear beams in the area of neutral fibers.

With types XY1, XY2 and XY4 we offer you strain gauges (SG) in various geometries and sizes, each available with temperature responses adapted to the following materials:

- Ferritic steel (10.8 ppm/K; 6.0 ppm/°F); temperature matching code: 1

- Aluminum (23 ppm/K; 12.8 ppm/°F); temperature matching code: 3

- Austenitic steel (16 ppm/K, 8.9 ppm/°F); temperature matching code: 5

- Silica/composite (0,5 ppm/K; 0.3 ppm/°F); temperature matching code: 6

- Titanium and gray cast iron (9 ppm/K; 5.0 ppm/°F); temperature matching code: 7

- Plastic (65 ppm/K; 36.1 ppm/°F); temperature matching code: 8

- Molybdenum (5.4 ppm/K; 3.0 ppm/°F - not available for XY1); temperature matching code: 9

Insert the temperature matching code in place of the placeholder “x” to get the ordering number of the strain gauge you need. Strain gauges marked with a # symbol are only available matched to aluminum, ferritic and austenitic steel

Save time and efforts: XY4 strain gauges are available as pre-wired versions with connection cable

Measuring grid consists of constantan, measuring grid carrier is polymide

Fast delivery for preferred strain gauge types - available from stock!

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Solder terminals are not compulsory | Preferred types | ||||

Measuring grid | Carrier | ||||||||

[Ω] | a | b1 | b2 | c | d | ||||

1-XY1x-1.5/350_E# | 350 | 1.5 | 2.2 0.087 | 2.9 0.114 | 7.8 0.307 | 4.9 0.193 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||

1-XY1x-3/350_E | 350 | 3 | 4.4 0.173 | 4.9 0.193 | 10 0.394 | 6.9 0.272 | LS5 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||

1-XY1x-6/350_E | 350 | 6 | 6.2 0.244 | 10.2 0.402 | 12.3 0.484 | 11.7 0.461 | LS4 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | |||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Maximum Excitation Voltage | Solder terminals | Preferred types | ||||

Measuring grid | Carrier | |||||||||

[Ω] | a | b1 | b2 | c | d | |||||

1-XY2x-0.6/120# | 120 | 0.6 | 2.2 0.087 | 1.1 0.043 | 7.5 0.295 | 4 0.157 | 2.5 | LS7 | - | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-1.5/120 | 120 | 1.5 0.059 | 1.7 0.067 | 2.5 0.098 | 6.8 0.268 | 4.5 0.177 | 4.5 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-3/120 | 120 | 3 0.118 | 3.7 0.146 | 5.3 0.209 | 11.2 0.441 | 9.5 0.374 | 6 | LS5 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-6/120 | 120 | 6 0.236 | 8 0.315 | 10 0.394 | 17.5 0.689 | 12.7 0.5 | 11 | LS4 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-1.5/350# | 350 | 1.5 0.059 | 2.2 0.087 | 2.5 0.098 | 7.4 0.291 | 4.5 0.177 | 5 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-3/350 | 350 | 3 0.118 | 4.2 0.165 | 5.3 0.209 | 11.2 0.441 | 9.5 0.374 | 10 | LS4 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-6/350 | 350 | 6 0.236 | 8 0.315 | 10 0.394 | 17.5 0.689 | 12.7 0.5 | 19 | LS4 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-3/700 | 700 | 3 0.118 | 4 0.157 | 4.7 0.185 | 11.2 0.441 | 9.5 0.374 | 14 | LS5 | - | |

Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY2x-6/700 | 700 | 6 0.236 | 7.8 0.307 | 9.2 0.362 | 17.5 0.689 | 12.7 0.5 | 27 | LS4 | - | |

Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

| Ordering number | Nominal (rated) resistance | Dimensions [mm/inch] | Maxmimum Excitation Voltage | Solder terminals are not compulsory | Preferred types | ||||

Measuring grid | Carrier | |||||||||

[Ω] | a | b1 | b2 | c | d | |||||

1-XY4x-0.6/120# | 120 | 0.6 | 2.2 0.087 | 1.6 0.063 | 6.5 0.256 | 4.6 0.181 | 1.5 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-1.5/120 | 120 | 1.5 | 1.8 0.071 | 3.1 0.122 | 7.5 0.295 | 4.6 0.181 | 2.5 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-3/120 | 120 | 3 | 3 0.118 | 5.4 0.213 | 11 0.433 | 8 0.315 | 5 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-6/120 | 120 | 6 | 6 0.236 | 10.2 0.402 | 16 0.63 | 12.2 0.48 | 9.5 | LS4 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-1.5/350# | 350 | 1.5 | 2.1 0.083 | 3.1 0.122 | 7.5 0.295 | 4.5 0.177 | 4 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-3/350 | 350 | 3 | 4.2 0.165 | 5.6 0.22 | 11 0.433 | 8 0.315 | 9.5 | LS7 | 1,3 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-6/350 | 350 | 6 | 6 0.236 | 10 0.394 | 16 0.63 | 12.2 0.48 | 16 | LS4 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-3/700 | 700 | 3 | 4.2 | 5.6 0.22 | 11 | 8 | 13.5 | LS7 | 1 | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

1-XY4x-6/700 | 700 | 6 | 6.1 | 9.9 0.39 | 16 | 12.2 | 23 | LS4 | - | |

| Steel (1) | Aluminum (3) | Austenitic Steel (5) | Silica / composite (6) | Titanium (7) | Plastic (8) | Molybdenum (9) | ||||||||||

Simplified Documentation and Parameterization

To optimize the measuring point documentation each strain gauge includes two stickers which can be placed next to the measuring point and near the measuring amplifier. Benefit from the parameter information directly in the measurement setup:

- QR code that directly links to the data sheet of the respective strain gauge

- The product and production batch numbers

- The k-factor and a additional space for your notes

- QR code containing the values of the individual strain gauge to simplify computer-aided parameterization or documentation with a scanner

Please note: newly produced strain gauges all come with the sticker in stock, strain gauges still in stock do not have this feature yet.

Product Literature

| Title / Description | Language | Products | Language | Content Types |

|---|---|---|---|---|

| Data Sheets | ||||

| Dehnungsmessstreifen - Katalog | German | |||

| Strain Gauges - Catalogue | English | |||

| Тензорезисторы - катало́г | Russian | |||

| Declaration of Conformity | ||||

| Strain Gauges and Accessories - Statement of Compliance | English | |||

| Tech Notes | ||||

| Determine the thermal expansion coefficient | English | |||

| Wärmeausdehnungskoeffizient bestimmen | German | |||