shock resistance of optical sensors

HBK Services for Monitoring of Wind Turbine Foundations

Geotechnical uncertainties and harsh environmental conditions make measurement of offshore installations and especially wind energy foundations a challenging task. Monitoring through continuous and reliable measurement and data analysis is a cost-effective solution to validate structural designs, aid operation and maintenance (O&M) decisions, and best support your energy assets over lifetime.

Here is how HBK can help:

Engineering Services

When measuring strain in a marine environment, particularly beneath the mud line, and in piled foundations, particular care is needed to give strain measurement technology the best possible chance to survive.

HBK project engineers have proven experience in the offshore wind industry. They help in the design, installation, and commissioning of the complete measurement system in such harsh environments – from sensor to resultant data

Choice of Technology

HBK offers tactile, robust and accurate sensing solutions – electrical and optical sensor technologies measuring physical quantities. These large offerings and expertise ensure reliable and complete measurement systems not only for short-term design validation work and load monitoring campaigns but also for long-term monitoring of structural health of offshore foundations, from the foot of the foundation to the tip of the blades.

HBK’s optical Fiber Bragg grating sensors are becoming increasingly trusted for these applications. With reduced installation costs, long-term stability and resistance to water and salt, optical sensors best fit the demands of harsh offshore wind turbine foundation monitoring. This, combined with the optical sensors inherent resistance to lightning strikes, makes the perfect fit for tower and blade monitoring. Low weight ensures the best chance of surviving piling, and utilising sensors in arrays minimises complexity.

HBK engineering services help you to design the optimum measurement chain covering critical measurement spots.

Sensor and Measurement Chain Installation

The performance of a measurement system, for example the quality of the measurement of a strain gauge, is hugely influenced by the quality of the installation – surface preparation, bonded or welded, measurement spot protection from salt water, temperature variations and other influences, and many more aspects are key to long-term reliable data.

HBK offers an installation service as well as regular training courses on strain gauge installation. Our project engineers have many years’ experience in performing the highest-quality installation possible for foundations destined for the sea.

From advice on measurement spots, soldering electrical cables and splicing optical fibers, to setting up the measurement and data acquisition (DAQ) and its software – pulling HBK into your project will ensure that projects are delivered quickly and competently – from sensor to result.

Sensor Protection and Quality

HBK has a proven method for the protection of measurement spots in the foundation of monopiles, jackets and gravity base structures used in the foundations of offshore wind turbines. Using highly reliable and field-proven material and following well-documented installation methods, HBK project engineers will ensure that both electrical and optical gauges have the best chance of surviving the effects of piling, submersion in water, and the long-term geotechnical issues that can cause bad data from a location often difficult or impossible to reach for investigation.

Benefits

Products for Individual Solutions

- Measurement of large bolts on large flange joints, calibrated if required

- Measurement beneath the seabed

- Additional tower and blade monitoring for a total load overview over time

- A wide range of versatile sensors coupled with class-leading DAQ and flexible monitoring software solutions

Global HBK Installation Service

- Strain measurement expertise

- Manpower for sensor and DAQ installation and commissioning

- Engineers with correct certification and considerable experience

- Quick and correct installation

- Almost anywhere in the world

Consultation Service

- Project engineers with in-field experience

- Advice on measurement positions

- Choosing the adequate measurement setup and the right products

- Ensuring your measurement spots are given the best protection, so they can survive as long as possible in the harshest environments

- Advice on 3rd party sensors to be used with HBK DAQ, such as accelerometers, inclinometers, and data from wave radar and other sensors.

Monitoring the Right Way with HBK

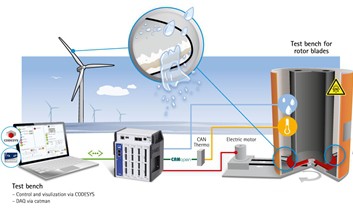

HBK offers complete measurement solutions that include reliable and accurate sensors, instruments and software to monitor components, rotor blades, towers and foundations.

The HBK service and solution team consists of skilled and certified project engineers providing professional on-site services and support – from sensor installation to result. For projects with large sensing networks, HBK also has a reliable and qualified partner network and can integrate with any cloud solution.

HBK offers systems and solutions for Structural Health Monitoring (SHM), Condition Monitoring (CM), and Structural Durability Testing based on either electrical or optical technologies, above and below the waterline, for either long- or short-term projects.

In addition, hybrid solutions with electrical strain gauges and optical instruments can be specifically configured to meet the guidelines of most applications.

HBK measurement technologies and systems can identify mechanical stress on wind turbine components at an early stage, enabling you to plan maintenance service actions ahead of time, and minimizing downtime.

With more than 60 years of know-how and expertise in strain measurements, structural durability analysis and testing and also experimental stress analysis, HBK can refer to a growing number of application references, involving major players around the world.

Enabling Data Cloud Services

With catman AP software, HBK offers the right software for structural health monitoring and an easy and flexible integration with any cloud service ensuring access to data that is relevant. The software offers links to the relevant data in your cloud:

Data package: multi parallel recorders with variable triggers (slow, fast), many different data formats, SFTP data transfer

Data stream: OPC UA, MQTT, CAN/CAN FD, EtherCAT, PROFINET, Modbus TCP, ….

Alarms/notifications: push commands

Questions? Contact us! We’ll be happy to advise you.

STRUCTURAL MONITORING

Structural analysis

Load monitoring

Blade design validation

Our Experience

Embedding of optical sensors to scrutinize local buckling behavior of the trailing edge of a wind turbine blade

CONDITION MONITORING

Fatigue analysis

Torque and force measurements

Our Experience

TEST AND MEASUREMENT APPLICATIONS

Loading by waves testing

Our Experience

Download our free Literature

| Titel / Beschreibung | Sprache | Produkte | Sprache | Inhalt |

|---|---|---|---|---|

| Download: Technischer Fachartikel / White Paper | ||||

| Foundation Monitoring – Resistive versus Fiber-Optical Strain Gauge Systems. Technology and Costs Compared. | English | |||

| Optimizing Structures with Continuous Monitoring Systems | English | |||