DIN EN ISO 376

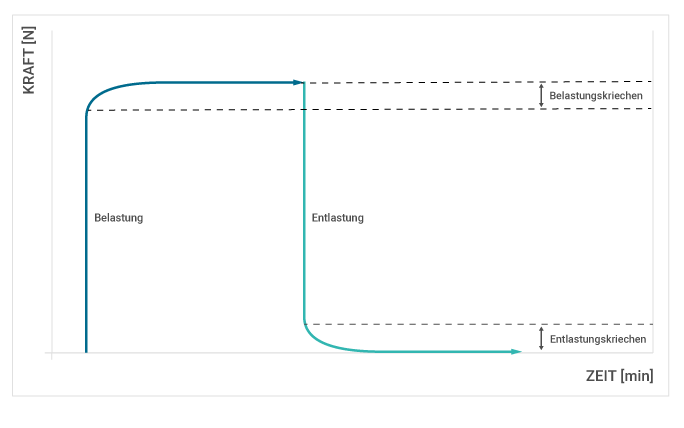

Die DIN EN ISO 376 beschreibt ein Kalibrierverfahren für Kraftaufnehmer oder Messketten (in der Norm wird allgemein von Kraftmessgeräten gesprochen), das für Sensoren angewendet wird, die als Referenzkraftaufnehmer bzw. als Transfernormal eingesetzt werden sollen bzw. greift, wenn es hohe Ansprüche an die Messunsicherheitsbestimmung gibt. Der Ablauf umfasst mehrmaliges Vorbelasten mit Nennkraft, stufenweises Belasten mit acht oder zehn Laststufen in drei jeweils um 120° gedrehten Einbaulagen und eine Kriechmessung.

Anschließend wird jedem kalibrierten Kraftaufnehmer ein Kalibrierschein beigefügt, der den Aufnehmer klassifiziert und die Kennwerte auswertet und dokumentiert. Ebenfalls enthält der Kalibrierschein Angaben zu der eingesetzten Kalibriereinrichtung, dem dabei verwendeten Messverstärker und den Umgebungsbedingungen, die bei der Kalibrierung vorlagen (Temperatur, Luftdruck, etc.)

Tipp: Hier finden Sie einen interaktiven Kalibrierschein. Die einzelnen Bestandteile einer Kalibrierung nach DIN EN ISO 376 werden Schritt für Schritt erklärt.