What characterizes a flexible tool for challenging tasks in a test and measurement environment?

Salcher:

"We studied the individual workflows of our customers, looking for a way to boost efficiency. We wanted to bring about a paradigm change – away from the permanently installed tool and towards an efficient one with daily-changing setups.

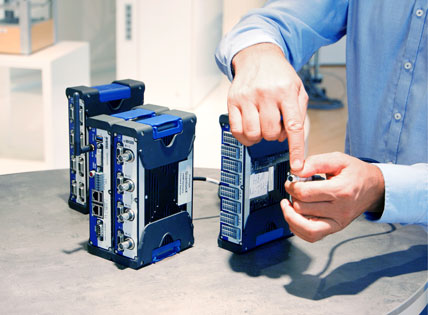

The format of the new system should be small and portable, accessing as many applications as possible. It should be installed close to the sensor to ensure shorter cable lengths, giving high quality measurement results in distributed mode. Changing requirements would be resolved with built-in functionality. It should be possible to integrate any measurement and any sensor you want quickly.

To further optimize our customers’ workflow, we paired the resulting demand for universal inputs with TEDS technology, where an electronic data sheet in the sensor or plug, combined with universal channels, increases the efficiency of automatic channel setup by around 70%. Of course, QuantumX was intended to be a reference point in terms of accuracy and precision and in no way inferior to the globally established MGCplus.

Another factor of course was the growing demand for higher dynamics. Machinery was becoming more dynamic and electrified. The signal bandwidths and sample rates should therefore fully encompass the vibroacoustic range, allow rotational analysis and be able to handle transient jobs with adequate resolution.

It was already apparent at the time that more and more measurement and testing tasks needed to run automatically and in combination with simulation models (today called ‘digital twin’) so that typical field and mobile test and measurement tasks would become reproducible and repeatable in a lab, or on a bench. Therefore, we needed to offer real-time integration into the emerging Ethernet-based fieldbuses, which, in 2008, were unique. However, in parallel with automation, measurement specialists, taking care of the test specimens, wanted to analyse their data whereas the test bench operator took care of the bench and its safety. And that is how the modular QuantumX came about, module by module, from one application to the next, always investigating the latest technical possibilities and their respective benefits for the user."