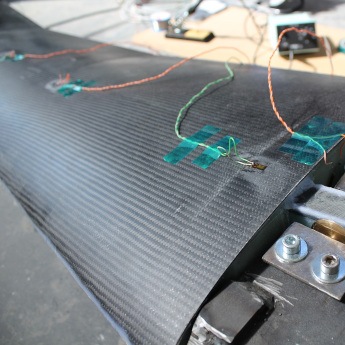

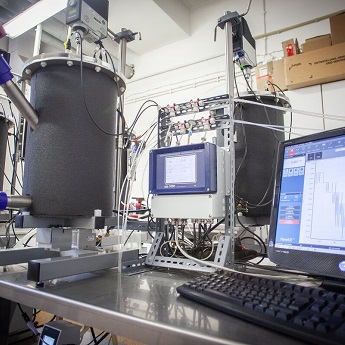

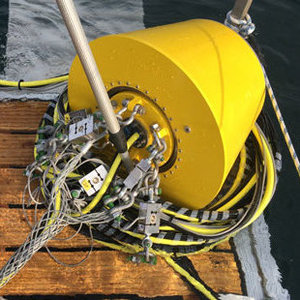

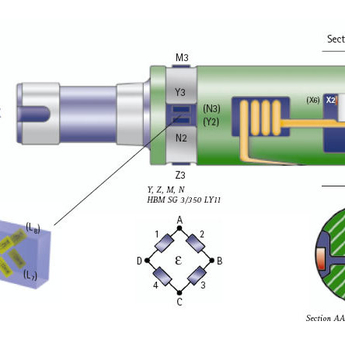

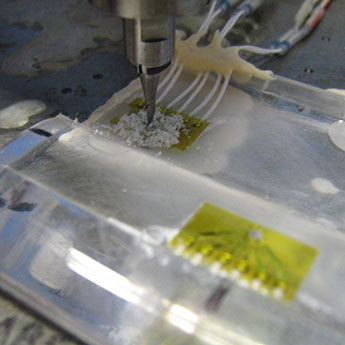

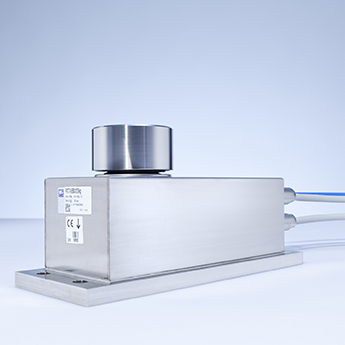

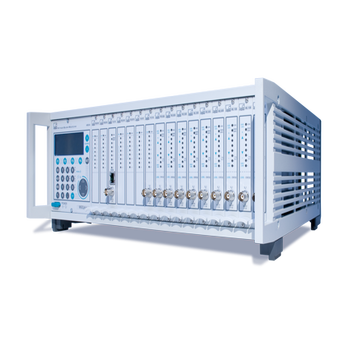

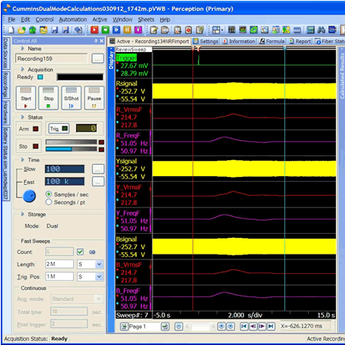

導入事例とケーススタディ

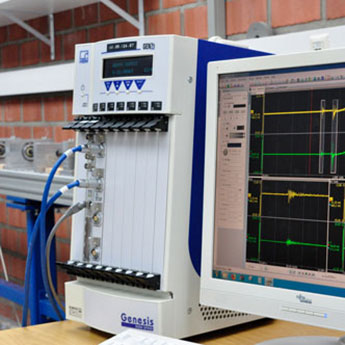

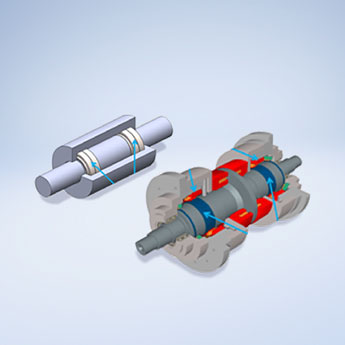

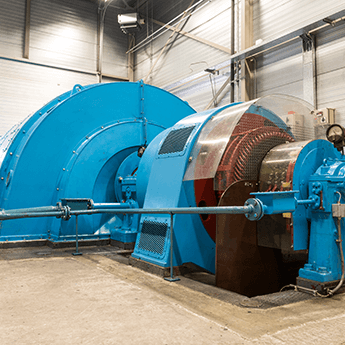

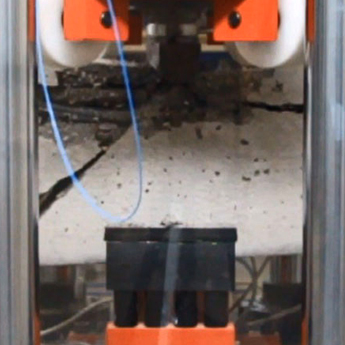

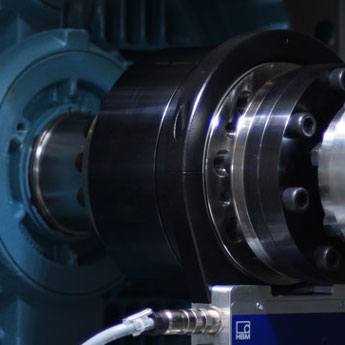

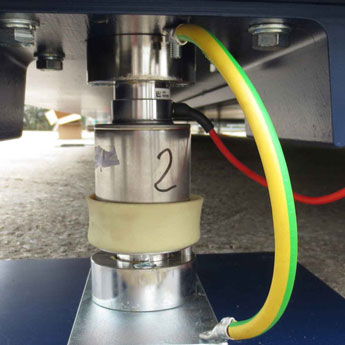

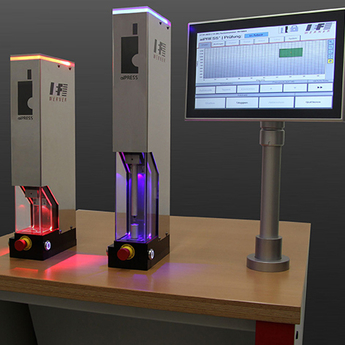

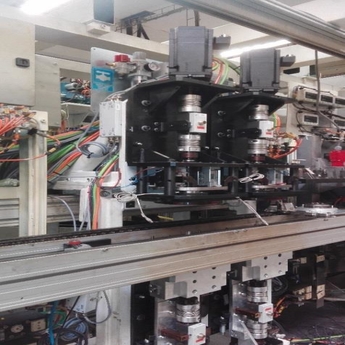

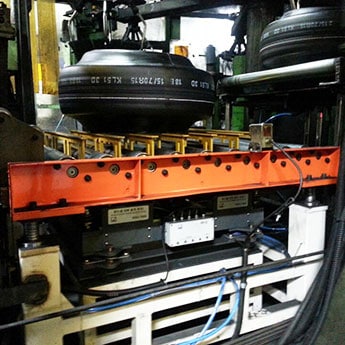

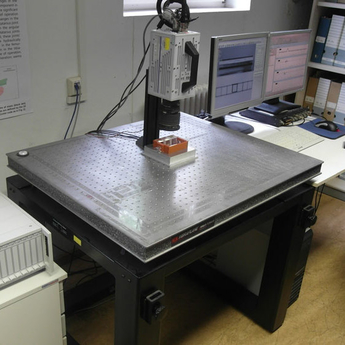

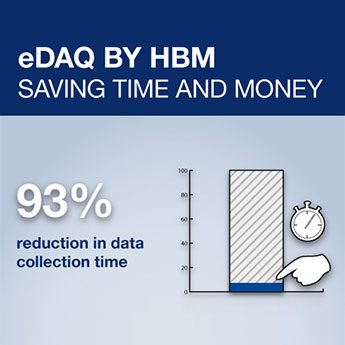

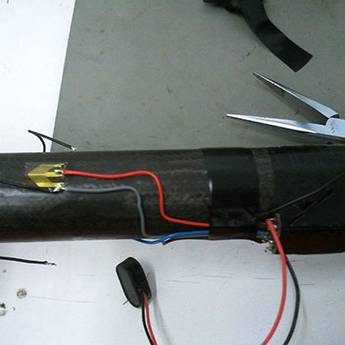

HBMセンサ、計測アンプ、ソフトウェアは、世界中のあらゆる産業分野において何千もの開発プロジェクトに使用されています。このページに集積された導入事例は、HBM製品の多様性を示しています。

ほぼ毎週、ここに新たな成功事例が追加されます。フィルタ機能を使ってご興味のある分野の事例をお選びいただくことも可能です。

またお客様からのアプリケーション事例も常時受けつけています。HBMのソリューションを使った導入結果の取材と掲載をご希望の方は、ぜひこちらからお問い合わせください。貴社の成功事例を世界に向けて発信し、共有いただくことで新たなイノベーションが生まれるかもしれません。